Omron 2013 Annual Report Download - page 18

Download and view the complete annual report

Please find page 18 of the 2013 Omron annual report below. You can navigate through the pages in the report by either clicking on the pages listed below, or by using the keyword search tool below to find specific information within the annual report.

32 Omron Corporation Integrated Report 2013 33

Where We're Headed

Collaboration between Industry,

Government, and Academia

to Invigorate Local Societies

As one way of rooting our operations to the regions

in which we work, we are placing an emphasis on

education, not only of our employees but also of the

students that will support the future of these regions.

Omron is working to share its corporate philoso-

phy with educators in Asia while also providing

opportunities for students to learn about environ-

mental issues and the latest technologies. At Chi-

nese vocational and technical colleges*, we help

teach students about manufacturing while they are

in school and hold Omron Classes, which attract vast

quality human resources. In addition, we hold the

Omron Cup Sterling Engine CAR Contest and design

contests, which are based on the themes of environ-

mental preservation and recycled resources. We also

hold the National University Student Photoelectric

hours a day doing nothing but confi rming variables.

By introducing computers equipped with data log-

ging software along with controllers, IAB helped

create a system in which all this numeric data is

recorded automatically by computers. This system

successfully reduced the amount of time employ-

ees devoted to these monitoring tasks to one hour a

day. Workers were thus freed from the task of con-

fi rming variables all day long, which in turn allowed

them to use this time to revise production process-

es and implement other improvement activities.

3. Automation Example (Thailand)

Electricity-Saving Initiatives

Rising costs in Thailand have resulted in a shift

toward less-wasteful activities at production sites.

Effi cient electricity use is being considered as one

way of realizing such activities. As such, factories

are increasingly introducing electricity monitoring

equipment, which can be used to track how much

electricity is being used in specifi c parts of a facility.

In order to respond to such global issues related to

safety and the environment as well as the need for

high-speed, high-precision control, IAB accumulates

cutting-edge technical expertise within its Automation

Centers* so that it may transmit unique technologi-

cal applications throughout the world.

* Automation Centers provide support services to help people make machines move

as they please. The support services provided by these centers include easing the

connection of equipment from different manufacturers, a task that previously

required substantial time investments, and assistance in realizing high-speed,

high-precision control for demanding pieces of machinery. Also, the centers help

customers quickly install machinery with ease. In these ways, the centers aid our

customers in developing competitive machinery setups.

Evolution Driven by Customer Needs

We work to address the various issues faced by

specifi c regions by developing solutions from the

perspective of local customers in these regions.

The number of products with different specifi ca-

tions produced by OMS has grown 2.5 times over

the past three years. When looking at the average

employee turnover rate in China, OMS has em-

ployee retention rates that are 3 to 5 times better

than the average. Nonetheless, its operations are

impacted by the rising labor costs and labor short-

falls in coastal areas. For this reason, OMS is em-

ploying Low Cost Intelligent Automation (LCIA) to

make its production operations in this country more

fl exible. Such fl exible production operations are

supported by small robots, a culmination of our

accumulated knowledge and expertise, and the

skills of employees are used to backup this system

while eliminating wastes.

Also, OMS is currently holding tours of its

factories for a wide range of visitors. We hope

that these tours will provide customers with a

model example to be considered in solving their

automation issues while at the same time offering

an opportunity for local companies to learn from

our production expertise.

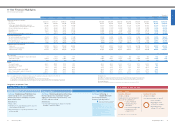

Source: Japan External Trade Organization (JETRO)

Note: Personnel expenses include basic salary, allowances, social security, overtime

payments, and bonuses.

Yearly Personnel Expenses

in Asia’s Manufacturing Sector

0

2,000

4,000

6,000

8,000

China Thailand Malaysia India Indonesia Vietnam Bangladesh MyanmarThe

Philippines

Fiscal 2009 Fiscal 2012

(US$)

Design Contest to help foster the development of

prospective automation engineers and provide edu-

cation regarding state-of-the-art technologies.

* Equivalent to technical colleges in Japan

Optimal Relationship between People

and Machines

Out of our development bases in Japan, Europe,

and the United States, we are able to develop an

understanding of the latest trends related to tech-

nologies and international standards. By leveraging

this advantage of our global operations, we hold

seminars and otherwise provide information to help

spread knowledge.

We also participate in committees for developing

safety standards. In such ways, we are working to

develop social foundations that enable a safe and

optimal relationship to be developed between

people and machines.

Pursuit of Further Evolution

The future of market conditions remains unclear.

Nevertheless, we will continue to take on new

challenges to create innovation while advancing

steady improvements through straightforward and

earnest effort. To this end, we are rethinking the

parts we use, reducing the number of parts con-

tained in our products, revising production pro-

cesses, and otherwise refi ning our technologies.

As automation spreads, people’s lives become

more fulfi lling, which in turn enables them to be more

creative at work, leading to the further evolution of

automation. Looking back at the history of automa-

tion, it is clear that demand for automation will con-

tinue growing into the future, as will its potential.

IAB will create cycles in which changes in soci-

ety’s needs and technical innovation give birth to

one another. And these cycles will be created

around the world. IAB will also work to grow as the

provider that is “No. 1 in control,” “No. 1 in product

lineup,” and “No. 1 in the future” so that it can

make greater contributions to the ever changing

Asian market.

We automate!

Soldering by hand

LCIA soldering robots

• Stable levels of quality

• Capital investment 1/3–1/4