Omron 2013 Annual Report Download - page 17

Download and view the complete annual report

Please find page 17 of the 2013 Omron annual report below. You can navigate through the pages in the report by either clicking on the pages listed below, or by using the keyword search tool below to find specific information within the annual report.

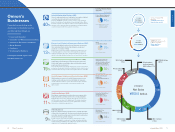

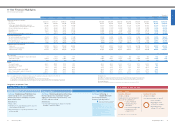

30 Omron Corporation Integrated Report 2013 31

Where We're Headed

Operations Well Established

in Each Country

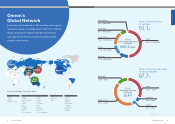

Industrial Automation Business (IAB) currently

operates out of more than 160 bases in more than

40 countries.

IAB was quick to expand operations into Asia, a

move that was partially based on geographic con-

siderations. Over half of the world’s population is

concentrated in this region, as emphasized by the

presence of such “populous giants” as China and

India, which boast the world’s fi rst and second

largest populations respectively, as well as by the

ASEAN countries, which collectively represent the

third largest population. Realizing the great poten-

tial for automation to contribute to the development

of Asia, we were not hesitant in fi rmly establishing

operations in this region, which we then utilized to

continue our ongoing pursuit to further the advance

of automation.

We began developing operations in China imme-

diately after Sino-Japan trade relations were re-

stored in 1972, and Omron founder Kazuma Tateishi

proceeded to deepen relationships with this coun-

try thereafter. In the 1980s, we began outsourcing

production to China, helping introduce our accumu-

lated Japanese production technologies into this

country. At the same time, we established sales

outlets in major operating bases, enabling us to

support the development of the Chinese economy

with our state-of-the-art automation equipment. In

the 1990s, we continued to develop production and

sales bases while working to make these bases

more locally operated. Later, in 2005, we consoli-

dated three factories in China to make a facility that

would become the core production and develop-

ment base for the global development of IAB. This

was the birth of Omron (Shanghai) Co., Ltd. (OMS).

Today, we have a comprehensive range of business

functions well-established in China, including pro-

duction, sales, development, planning, services,

support, and research functions.

In addition, IAB has 98 sales bases in 11 coun-

tries throughout Asia, including Japan.

The development of operations in the Asia Pacifi c

region began with the establishment of the OM-

RON Singapore PTE LTD. in 1972. Later, we estab-

lished our fi rst production base in Malaysia. Since,

we have continued to be a leader in Asia, quickly

developing operations that are fi rmly established in

Hong Kong, Taiwan, China, Indonesia, Thailand,

Vietnam, India, and other areas.

Connection of Customer Feedback

to All Areas of Operation

Today, it is more important than ever for us to posi-

tion ourselves closer to customers so that we can

quickly recognize their needs and use these to

drive change. It is important to refl ect market

needs and changes as well as customer feedback

into our products and services. Further, the feed-

back gained from customers who use the products

and services created through this process must

once again be incorporated into products and ser-

vices to spur us forward on the path of constant

evolution. Through the ever revolving cycle of incor-

porating customer feedback into products and ser-

vices, we are actively adapting our operations

to the characteristics of individual regions.

This cycle has led to the development

of a rich lineup of services and support.

For example, our free e-learning courses

are a form of service and support born out

of the demand for ways to quickly and easily

learn about the latest products and technologies.

These courses provide comprehensive explana-

and medicine bottles in India was often poor, and

bottles with chipped or warped mouths were fre-

quently shipped and sold at stores. However, con-

sumers became more sensitive toward the quality

and safety of the products they purchased, and this

resulted in a movement devoted to preventing

manufacturers from placing bottles with quality

issues on the market. To support this movement,

IAB supplied visual sensing equipment that was

able to analyze the condition of bottle mouths from

recorded images. This enabled all bottles to be

quickly and automatically inspected, thereby pre-

venting the shipment of low-quality bottles.

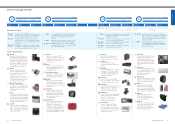

Metal Processing Equipment

Company C is a manufacturer of metal processing

equipment. This company recognized the need to

ensure worker safety, but at the same time it want-

ed to avoid declines in production volumes or pro-

ductivity that would have resulted from excessive

safety measures, such as fencing off all machines.

IAB helped this company realize a workplace that

is both safe and productive by utilizing the safety

sensors that are standard equipment on machinery

in developed nations. These sensors were placed

in optimal positions around areas where danger

was present.

2. Automation Example (Indonesia)

Food Production Equipment

Company D is a sugar manufacturer. At the com-

pany, employees previously had to directly confi rm

temperature, humidity, and other variables related to

the sugar refi ning processes and then record this

information in production logs by hand. For this

reason, employees were unable to leave refi ning

equipment unattended, and they often spent eight

tions of the fundamental mechanisms of equip-

ment and their usage and are made available in

13 languages, including English, Chinese, Vietnam-

ese, Thai, and Indonesian.

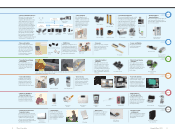

Evolution of Automation

In Asian countries, global issues must be addressed

in conjunction with region-specifi c issues.

1. Automation Examples (India)

Food Packaging Equipment

Company A is a food packaging equipment manu-

facturer. As consumption trends accelerated in India,

this company was faced with the need to further

expand its production volumes. However, the equip-

ment control system it possessed was unable to

respond to the higher production volumes. To ad-

dress this issue and improve productivity, IAB

helped the company shift to a state-of-the-art sys-

tem combining controllers and motion, which real-

ized substantial improvements in processing speed

and control precision in comparison to the previous

system. After the shift, the company was able to up

its production volumes 1.5 times, enabling it to pro-

vide customers with a stable supply of products.

Food Product Inspection Equipment

Company B is a manufacturer of food product in-

spection equipment. In the past, the quality of drink

Repair center in Thailand

Development and

Product Improvement

Bases

Japan, China

Repair Centers

Japan, China, Taiwan, Singapore,

Thailand, Malaysia, India, Vietnam,

Indonesia, the Philippines

Automation Centers

Japan, China, India (Planned)

Call Centers

Japan, China

Help Desks for

Japanese Customers

China (Shanghai, Beijing, Guangzhou),

Thailand, Indonesia

Sales Bases

Japan: 27, South Korea: 4,

Greater China: 53, Asia Pacific: 14

Shanghai Plant

Malaysia Plant

Indonesia Plant

e-Learning Programs—Virtual FA Tours

Vietnamese

Thai

Indonesian