Omron 2013 Annual Report Download - page 16

Download and view the complete annual report

Please find page 16 of the 2013 Omron annual report below. You can navigate through the pages in the report by either clicking on the pages listed below, or by using the keyword search tool below to find specific information within the annual report.

28 Omron Corporation Integrated Report 2013 29

Where We're Headed

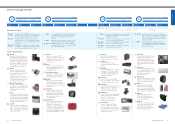

Factory Automation (FA) Growing

Together with People’s Lives

Evolution of Automation

at Production Sites

By supporting factories, Omron has continued to

contribute to the daily development of a more ful-

fi lling and convenient society.

As the focus of production activities changed

from people to machines, we have continued to

advance technological innovation in the fi eld of FA.

In the mid-20th century, automation was advanc-

ing in strides in developing nations. Omron de-

clared 1955 as “Year One of Automation.” It was

one of the fi rst companies in Japan to begin devel-

oping and promoting the spread of relays, timers,

and switches, all items that are indispensable in

automating the movement of machines. Through

those efforts, Omron helped drive the shift from

people to machines as agents of production, there-

by reducing human error brought about by extend-

ed work periods and subsequently improving

production effi ciency and making workplaces safer

for people.

At the same time, we developed the base for

mono zukuri (manufacturing) technology, which

encompasses all aspects of product creation, includ-

ing production and other processes, management

systems, and quality management techniques.

Omron created the world’s fi rst contactless switch,

which contributed to the development of machines

that could conduct mass production without wear

or malfunction. The realization of mass production

resulted in an ample supply of products being put

on the market, helping consumers acquire the

items they need with greater ease.

In 1972, Omron successfully developed its Sys-

mac programmable controller and continued to lead

the advance of automation by proposing new value

using its revolutionary technologies, such as its

ultra-high-speed fuzzy logic controller and visual

sensors that can play the part of human eyes, both

world fi rsts. The advance of automation drove

growth in the economy, which in turn made peo-

ple’s lives more comfortable and convenient. We

believe that such automation advancements made

substantial contributions to Japan’s period of strong

economic growth.

Development of Safer Workplaces

The advance of automation led to a decline in the

need for humans to conduct dangerous tasks.

However, as machines became more powerful,

they eventually came to pose risks to people.

Omron identifi ed that guaranteeing the safety of

machines toward humans is an important theme

and developed safety sensors, which automatically

halt dangerous machines should a worker approach

them, and safety door switches that prevent work-

ers from approaching dangerous machines in the

fi rst place. At the same time, Omron actively pro-

moted the standardization of automation safety

regulations and transmitted information to educate

the market with regard to safety, working to create

safer production sites around the world.

Preservation of Natural Resources

When considering natural resources, it is clear

that the energy used by machinery and the impure

substances they emit represent serious environ-

mental issues.

Omron has been proactive in making the automa-

tion equipment it produces lead-free and therefore

more eco-friendly. In addition, we have developed

more precise control technologies to prevent mate-

rials from going to waste due to the production of

defective products.

To lower energy consumption, which is particu-

larly high in the manufacturing industry, we have

developed an array of sensing, display, and control

equipment that contributes to energy savings. Fur-

ther, we have created means of applying “Sensing

and Control” technologies to energy to reduce

consumption, and these technologies have been

introduced into Omron’s own production sites.

• Particle Sensors

Measure dust in

clean rooms and

equipment

• Temperature and

Humidity Sensors

• Differential Pressure Sensors

Measure pressure differences

between clean rooms and

the outside environment

For Environmental Preservation

Core Theme

1Industrial Automation Business (IAB) and Emerging Countries

History of Automation

and Asian Market of Today

• Electricity monitors

Measure electricity

usage

Future Potential of Automation

FA around the World

Automation has undergone a startling evolution in

Japan over the years. Today, the contributions of

automation’s evolution are everywhere and automa-

tion technologies have spread throughout the lives

of countless people.

• Safety Light Curtains

Halt machines when

a person approaches

For Safer Workplaces

• Safety Door Switches

Halt machines when

doors are opened