Occidental Petroleum 2001 Annual Report Download - page 8

Download and view the complete annual report

Please find page 8 of the 2001 Occidental Petroleum annual report below. You can navigate through the pages in the report by either clicking on the pages listed below, or by using the keyword search tool below to find specific information within the annual report. synergist

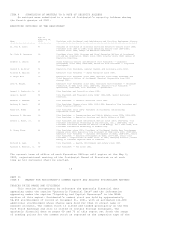

----------------------- ---------------------------------------- ------------------------------------------------------

Vinyls Vinyl chloride monomer (VCM) Raw material for polyvinyl chloride

---------------------------------------- ------------------------------------------------------

Polyvinyl chloride resin PVC pipe for municipal, plumbing and electrical uses.

External construction materials such as window and

door profiles, fencing, and decking. Flooring, medical

and automotive products, wire and cable insulation,

and packaging.

----------------------- ---------------------------------------- ------------------------------------------------------

Specialty Vinyls Polyvinyl chloride (PVC) resin and films Resins for flooring, medical gloves and other flexible

vinyl applications. Calendered films for automotive,

packaging and consumer products

----------------------- ---------------------------------------- ------------------------------------------------------

RAW MATERIALS

Nearly all raw materials used in OxyChem's operations are readily available

from a variety of sources. Most of OxyChem's key raw materials purchases are

made through both short and long-term contracts. OxyChem is not dependent on any

single nonaffiliated supplier for a material amount of its raw-material or

energy requirements. Equistar supplies virtually all of the ethylene

requirements (up to 2.55 billion pounds per year) for OxyChem's chlor-alkali

business and OxyVinyls' business. Although earnings have been adversely affected

by higher natural gas, electricity and feedstock prices for most of the past

year, operations have not been curtailed as a result of any supply

interruptions.

PATENTS, TRADEMARKS AND PROCESSES

OxyChem owns and licenses a large number of patents and trademarks and uses

a variety of processes in connection with its operations, some of which are

proprietary and some of which are licensed. OxyChem does not regard its business

as being materially dependent on any single patent, trademark or process.

SALES AND MARKETING

OxyChem's products are sold to industrial users or distributors located in

the United States, largely by its own sales force. OxyChem sells its products

principally at current market or current market-related prices through both

short and long-term sales agreements.

No significant portion of OxyChem's business is dependent on a single

third-party customer. However, OxyChem has entered into significant supply

arrangements with certain of its affiliates. In 2001, PolyOne purchased raw

materials pursuant to PVC resin and VCM sale contracts at market-related prices

from OxyVinyls valued at approximately $184 million. Consequently, changes in

demand by PolyOne will affect OxyVinyls. In addition, in 2001, OxyChem and

OxyMar purchased a combined total of approximately $490 million of ethylene at

market-related prices from Equistar. Finally, OxyMar, which is OxyChem's

affiliate, sold VCM resin at market-related prices valued at approximately $291

million to OxyChem affiliates in 2001. In general, OxyChem does not manufacture

its products against a backlog of firm orders.

7

COMPETITION

The chemical business is very competitive. Since most of OxyChem's products

are commodity in nature, they compete primarily on the basis of price, quality

characteristics and timely delivery. Because OxyChem's products generally do not

occupy proprietary positions, OxyChem endeavors to be an efficient, low-cost

producer. OxyChem's size and the number and location of its plants also produce

competitive advantages, principally in its ability to meet customer delivery

requirements.

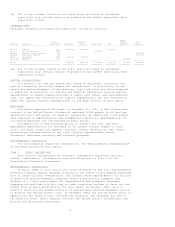

PROPERTIES

As of December 31, 2001, OxyChem, which is headquartered in Dallas, Texas,

operated 27 chemical-manufacturing plants in the United States. Many of the

larger facilities are located in the Gulf Coast areas of Texas and Louisiana. In

addition, OxyChem operates six chemical-manufacturing plants in four foreign

countries; its largest investment is in Brazil. A number of additional

facilities process, blend and store the chemical products. OxyChem owns or

leases an extensive fleet of railroad cars.

All of OxyChem's chemical-manufacturing plants are owned, except for a

portion of OxyVinyls' plant at La Porte, Texas, which is leased. The charts

below list OxyChem's principal facilities and plant capacities.