Hyundai 2009 Annual Report Download - page 17

Download and view the complete annual report

Please find page 17 of the 2009 Hyundai annual report below. You can navigate through the pages in the report by either clicking on the pages listed below, or by using the keyword search tool below to find specific information within the annual report.

A World-Leading Global Production Network

Korea

Ulsan I As Hyundai Motor’s main production facility, the Ulsan Plant sits on a

5,050,000 m

2

site and is equipped with five independent plants that employ over

34,000 personnel to produce an average of 5,400 vehicles a day. Additionally, the

plant has its own port where up to three, 50,000-ton ships can anchor simultane-

ously. The Ulsan Plant, also dubbed the “Forest Plant,” encompasses 580,000

trees as part of its landscape and state-of-the-art facilities.

Asan I With an annual capacity of 30,000 units, the Asan Plant is an entirely self-

contained, independent automobile production complex that mainly produces

stra-

tegic mid -to large-size passenger cars for export. The Asan Plant offers a bright and

pleasant, people-oriented and nature-inspired working space, and has proven

that

the quality of the working environment determines the quality of products.

Jeonju I With an annual production capacity of 125,000 units, the Jeonju Plant

specializes in producing mid-to large-size buses, trucks, and specialty vehicles

that exceed 2.5 tons.

Overseas

America I Within one year after it began mass production in May 2005, the Ala-

bama Plant achieved the incredible feat of being placed 10th in product quality

among 37 plants in North America. It focuses on mid-to full-size vehicles, and con-

tinues to live up to its reputation as a comprehensive automobile plant that applies

the latest technologies and techniques to its production lines.

China I In addition to the existing first plant, a second plant with an annual ca-

pacity of 300,000 units was added to the China Plant, increasing its total annual

production capacity to 600,000. The plant is a reassuring foothold in securing a

sizable share in the automobile market in China, which is rapidly becoming a global

economic powerhouse.

India I A comprehensive, self-sufficient automobile plant that focuses on the R&D,

testing, manufacturing, and sales of new products that are adapted to the Indian

market, the India Plant added a second plant in 2008 to achieve an annual pro-

duction capacity of 600,000 units. It serves as an overseas manufacturing plant

for compact cars, such as the first overseas-specific model i10 and the strategic

European model i20. It has accomplished much in India’s automobile industry,

including setting a production record of 2,500,000 units and sales of 1,000,000

units in the shortest time, and is responsible for 20% of the market share and

66% of the automobile export in India.

Turkey I The expansion of the Turkey Plant in March 2007 resulted in an increase

in the annual pro

duction capacity from 60,000 units to 100,000 units. A strategic

foothold that connects Europe, Africa, and the Middle East, the Turkey Plant plays

a key role in the increase of exports from the region through the localization of the

Accent and i20 models.

Czech Republic I Nineteen months after its historic groundbreaking, the Czech

Republic Plant commenced mass production in November 2008. The Czech Re-

public Plant focuses on a strategy of full localization to develop models geared to

the tastes of European consumers. Taking full advantage of its strategic location in

the center of Europe, the Czech Republic Plant will be a stepping stone to Hyun-

dai’s expansion into the European market.

Russia I Scheduled to commence mass production in January 2011, the Russia

Plant is the only auto plant in Russia that can handle the entire manufacturing

process of complete units. The plant will start off with an annual production

of 100,000 units, which will eventually increase to 150,000 units. Comprised of

expert employees trained in Korea and in the Czech Republic, the Russia Plant will

focus on production of the C-Class models with reinforced designs adapted to the

local needs in Russia.

Brazil I The Brazil Plant will secure a manufacturing foothold in the biggest market

in Central and Latin America and play an important role in increasing sales in the re-

gion. The Brazil Plant will be producing stylish and fuel efficient compact cars suited

for the Brazilian market, and contribute to increasing the market share in the region.

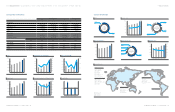

2009 Annual Production of

Overseas

Plants

(Unit : ‘000 units)

2009 Annual Production of Domestic Plants

(Unit : ‘000 units)

U.S.A

Ulsan

China India

Asan

Turkey Czech

Jeonju

400

600

1,500

200

1,000

100

500

10

100

1,301

250

196

571 560

118

49

56

>>

GLOBAL PRODUCTION SYSTEM

Hyundai Motor Company,

Creating Your Lifestyle

Customers have different needs, different tastes,

and different lifestyles. Our global network of state-

of-the-art manufacturing plants makes cars that fit

the lifestyle of each and every one of our customers

.

Ulsan Plant

Alabama Plant

India Plant

HYUNDAI MOTOR COMPANY I 2009 ANNUAL REPORT I 33HYUNDAI MOTOR COMPANY I 2009 ANNUAL REPORT I 32

INTRO I FINANCIAL HIGHLIGHTS I MESSAGE FROM THE CEO I TO TRUTH I TO POWER I HYUNDAI WITH THE WORLD I TO FUTURE I HYUNDAI WITH HONESTY I SUPPLEMENT I FROM HYUNDAI