Cemex 2013 Annual Report Download - page 19

Download and view the complete annual report

Please find page 19 of the 2013 Cemex annual report below. You can navigate through the pages in the report by either clicking on the pages listed below, or by using the keyword search tool below to find specific information within the annual report.

Moreover, we are continuously evaluating investment

opportunities in the development of new energy proj-

ects. In Mexico, we are in the process of developing

a series of energy projects, beginning with the con-

struction of the Ventika wind-powered energy park

in the northern state of Nuevo Leon. With a minority

equity stake not exceeding 5%, our primary role will be

to provide technical expertise for the development of

these projects.

To further minimize the ecological impact of our oper-

ations, we continue our efforts to replace clinker with

alternative cementitious materials—many of which are

derived from the waste of other industries. Materials

that we are using instead of clinker include fly ash from

power plants, blast furnace slag from pig iron produc-

tion, and volcanic ash. In 2013, our overall clinker factor

(the ratio of clinker content to total cement production)

was reduced by approximately 8% when compared to

our baseline year of 1990.

In 2013, we successfully obtained the United Nations Framework Convention on

Climate Change (UNFCCC) accreditation for six new initiatives as Clean Development

Mechanisms (CDM), including projects in Mexico and Panama. Overall, our full CDM

portfolio now includes 19 officially registered projects for a total carbon offset po-

tential of 2.44 million tons of CO2 emissions per year. In addition, CEMEX registered a

carbon reduction project in Miami, Florida, under the Verified Carbon Standard (VCS),

the world’s leading voluntary greenhouse gas program. Together with our project in

Louisville, Kentucky, which we registered in 2012, these projects represent an annual

reduction potential of more than 360,000 tons of CO2. Our full portfolio has the po-

tential to mitigate a total of approximately 2.8 million tons of CO2 per year.

UNFCCC accreditation for new initiatives

Responsibly managing

biodiversity and water

Beyond reducing our carbon footprint, we work diligently

to responsibly manage the habitat within and around our

operations to protect biodiversity and maximize our con-

tribution to nature conservation. To this end, we continue

working to develop quarry rehabilitation plans for all of

our active cement and aggregates sites.

Moreover, our biodiversity management recently earned

accolades from the European Aggregates Association.

Specifically, our Soto Pajares Quarry in Spain won the

Special Award for Biodiversity at the 2013 Sustainable

Development Awards for its outstanding protection,

enhancement, and creation of key habitats for important

species. Also, our Rugeley Quarry in the United Kingdom

received the Recognition of Achievement for its signifi-

cant restoration work and excellent habitat management

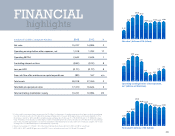

Net specific CO2

emissions reduction

(from our 1990 baseline)

-24%

1990 2013

Indeed, as compared with our 1990 baseline, at the end

of 2013, we had achieved a reduction of approximately

24% in our specific net CO2 emissions per ton of cement

produced. Consequently, for the year, we avoided ap-

proximately 7 million metric tons of CO2 emissions—in-

cluding emissions avoided through the EURUS wind farm

in Mexico. This is equal to the emissions generated by

1.35 million passenger vehicles per year.

Soto Pajares Quarry, Spain

[18]