Cemex 2013 Annual Report Download - page 12

Download and view the complete annual report

Please find page 12 of the 2013 Cemex annual report below. You can navigate through the pages in the report by either clicking on the pages listed below, or by using the keyword search tool below to find specific information within the annual report.

Employing decades of experience delivering tailor-made

solutions for projects in developed and developing econ-

omies, we work with our customers around the world to

build sustainable, industry-leading infrastructure that will

enable our communities to thrive today and well into the

future. This year, we participated in a number of high-

scale infrastructure projects, including Panama’s Coast-

al Beltway, one of the most important transportation

initiatives in the nation’s capital. To satisfy the project’s

demanding requirements, we designed and delivered

nearly 130,000 cubic meters of specialty added-re-

sistance concrete for maritime use in the construction

of transversal and longitudinal beams, foundations, and

jetties for this new phase of the beltway. In Israel, we

supplied our structural expertise, along with approxi-

mately 100,000 cubic meters of specialty ready-mix

concrete, to satisfy the engineering complexities of the

first stage of Israel’s new national railway. In England, we

provided our custom-made ready-mix concrete, coupled

with our industry-leading logistical expertise, for one

of the 80-meter deep shafts of the Thames Water Lee

Tunnel in Greater London. To meet the project’s challeng-

ing material requirements, three cranes delivered 11,000

cubic meters of ready-mix concrete over 29 uninter-

rupted days, one of the longest continual slip form pours

recorded in Europe.

Delivering industry-leading

building solutions

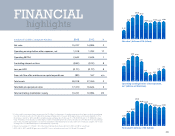

Concrete vs. asphalt pavement

Concrete pavement solutions provide significant advantages over asphalt; its

excellent surface finish, superior durability, and low total cost over the full life

cycle make it the material of choice.

Concrete roads can be designed for 50

years or more, and they last around

three times longer than asphalt roads

before a first major rehabilitation is

required.

Including the full lifecycle of the proj-

ect, concrete has a significantly lower

total cost versus asphalt, despite its

slightly higher initial cost.

Cities are warmer than their surroundings,

which in summer leads to discomfort,

medical conditions, and higher air condi-

tioning use. Light-colored surfaces with

high reflectivity, such as concrete, reduce

this so-called urban “heat island” effect.

On the rigid surface of a concrete

pavement, wheels do not sink in as

much as they do on flexible (i.e., asphalt)

pavements. This effect, called deflection,

is invisible to the naked eye, but has a no-

ticeable impact on vehicle fuel efficiency.

We provided our cus-

tom-made ready-mix

concrete for one of the

80-meter deep shafts of the

Thames Water Lee Tunnel in

Greater London, England.

Asphalt

Concrete

Initial Total

Maintainance

Present value

0 10 20 30

Asphalt

Concrete

Superior

durability

Lower cost

over full life

cycle

Reduced "heat

island" effect

Lower

vehicle fuel

consumption

Time for first rehabilitation

(highways indicative) - years

Total life-cycle cost

Rigid pavement

Concrete

Flexible pavement

Asphalt

Base cost = 100

Concrete Asphalt

[11]