ADT 2004 Annual Report Download - page 44

Download and view the complete annual report

Please find page 44 of the 2004 ADT annual report below. You can navigate through the pages in the report by either clicking on the pages listed below, or by using the keyword search tool below to find specific information within the annual report.

SEGMENT REVIEW

Q: WHAT ARE YOUR KEY TARGET MARKETS, AND HOW ARE YOU

SERVING THEM?

In total, our segment tracks 24 customer cate-

gories that fall into two primary markets: retail,

including the do-it-yourself market; and indus-

trial or business-to-business.

For both of these primary markets, we’ve estab-

lished strategies and investment plans. For example,

we initiated a new Key Account Management pro-

gram in 2004 that identifies and prioritizes key and

target customer accounts within each market. In

developing these Key Account Management plans,

we also identified the top satisfaction criteria for

each customer. Relying heavily on Six Sigma tools,

we partnered with our customers to develop and

validate their requirements. We’re now focusing our

resources on meeting those requirements to win a

larger percentage of their business.

Q: WHAT WERE YOUR KEY INITIATIVES AND BIGGEST SUCCESSES

IN 2004?

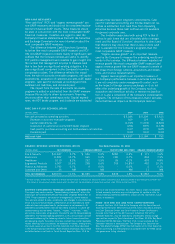

In 2004, we spent the year building a strong manage-

ment team, increasing productivity to improve our

competitiveness, and driving improved cash flow

generation. On all fronts, I’m proud of our results.

Our first task was essentially building a new

leadership team from scratch. All but two members

of our leadership team in Plastics & Adhesives

joined us within the last two years. One important

distinction about our leadership team is that 10 of

us are trained as Six Sigma Green Belts, Black Belts,

or Master Black Belts—a further illustration of our

commitment to operational excellence.

The primary mission of our leadership team

in 2004 was to improve productivity and drive costs

from our businesses, focusing on restructuring,

sourcing, supply chain management, Six Sigma, and

lean. All these initiatives combined to create nearly

$45 million in savings. In terms of cash flow, we

achieved a 14 percent improvement in working

capital days.

Although we have several success stories, I’m

particularly proud of what we achieved through

our restructuring initiative. At the beginning of

fiscal year 2004, we had far too much manufactur-

ing capacity versus market demand, to the point

that our plants on average were operating at only

73 percent of capacity. Through a sustained team

effort, we closed nearly 30 facilities, representing

about 2 million square feet. We also relocated multiple

production lines that handled 100 million pounds

of product. As a result of these projects, we signifi-

cantly increased our plant capacity utilization and

expect to achieve increased savings in the future.

Q: YOUR SEGMENT HAS BEEN FACING ONE OF THE MOST PER-

SISTENTLY TOUGH BUSINESS ENVIRONMENTS IN RECENT

MEMORY. WHAT ARE YOU DOING TO STAY AHEAD OF THESE

CHALLENGES?

Over the last two years, we have faced an unusual

challenge in the form of sustained cost increases

for resin, a critical raw ingredient used to make

WITH A PORTFOLIO OF LEADING PRODUCTS THAT INCLUDES

STRETCH FILMS, PLASTIC SHEETING, GARMENT HANGERS, AND DUCT TAPE, TYCO

PLASTICS & ADHESIVES IS EVERYWHERE. SEGMENT PRESIDENT TERRY SUTTER

AND HIS TEAM ARE BUILDING A PLATFORM FOR SUSTAINABLE GROWTH AND

IMPROVED FINANCIAL PERFORMANCE.

Q&A WITH:

TERRY A. SUTTER

President

Tyco Plastics & Adhesives

TYCO

PLASTICS &

ADHESIVES

42