Sunoco 2013 Annual Report Download - page 13

Download and view the complete annual report

Please find page 13 of the 2013 Sunoco annual report below. You can navigate through the pages in the report by either clicking on the pages listed below, or by using the keyword search tool below to find specific information within the annual report.

11

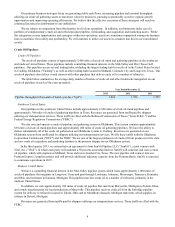

The following table shows the average shipments on the refined products pipelines in each of the years presented.

Average shipments represent the average revenue-generating pipeline throughput:

Year Ended December 31,

2013 2012 2011

Pipeline throughput (thousands of bpd)(1)(2) 571 582 522

(1) Excludes amounts attributable to equity ownership interests in corporate joint ventures which are not consolidated.

(2) In May 2011, we acquired a controlling financial interest in Inland and we accounted for the entity as a consolidated subsidiary from

the date of acquisition. Average volumes for the year ended December 31, 2011 of 88 thousand bpd have been included in the

consolidated total. From the date of acquisition, this pipeline had actual throughput of 140 thousand bpd for the year ended

December 31, 2011.

The mix of refined products delivered varies seasonally, with gasoline demand peaking during the summer months, and

demand for heating oil and other distillate fuels peaking in the winter. In addition, weather conditions in the areas served by the

Refined Products Pipelines affect both the demand for, and the mix of, the refined products delivered through the pipelines,

although historically any overall impact on the total volume shipped has been short-term.

Joint Ventures

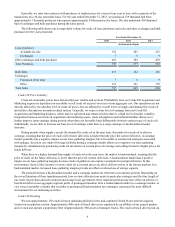

We own equity interests in several common carrier refined products pipelines, summarized in the following table:

Pipeline SXL Equity Ownership Approximate Pipeline Mileage

Explorer Pipeline Company (1) 9.4% 1,850

Yellowstone Pipe Line Company (2) 14.0% 700

West Shore Pipe Line Company (3) 17.1% 650

Wolverine Pipe Line Company (4) 31.5% 700

(1) The system, which is operated by Explorer employees, originates from the refining centers of Beaumont, Port Arthur and Houston,

Texas, and extends to Chicago, Illinois, with delivery points in the Houston, Dallas/Fort Worth, Tulsa, St. Louis, and Chicago areas.

Explorer charges market-based rates for all its tariffs.

(2) The system, which is operated by Phillips 66, originates from the Billings, Montana refining center and extends to Moses Lake,

Washington with delivery points along the way. Tariff rates are regulated by the FERC for interstate shipments and the Montana

Public Service Commission for intrastate shipments in Montana.

(3) The system, which is operated by Buckeye, originates from the Chicago, Illinois refining center and extends to Madison and Green

Bay, Wisconsin with delivery points along the way. West Shore charges market-based tariff rates in the Chicago area.

(4) The system, which is operated by Wolverine employees, originates from Chicago, Illinois and extends to Detroit, Grand Haven, and

Bay City, Michigan with delivery points along the way. Wolverine charges market-based rates for tariffs at the Detroit, Jackson,

Niles, Hammond, and Lockport destinations.

Pipeline and Terminal Control Operations

Almost all of our pipelines are operated via satellite, microwave, and frame relay communication systems from central

control rooms located in Sugar Land, Texas and Montello, Pennsylvania. The Sugar Land control center primarily monitors and

controls our Crude Oil Pipelines, and the Montello control center primarily monitors and controls our Refined Products

Pipelines. The Nederland Terminal has its own control center.

The control centers operate with Supervisory Control and Data Acquisition, or SCADA, systems that continuously

monitor real time operational data, including throughput, flow rates, and pressures. In addition, the control centers monitor

alarms and throughput balances. The control centers operate remote pumps, motors and valves associated with the delivery of

throughput products. The computer systems are designed to enhance leak-detection capabilities, sound automatic alarms if

operational conditions occur outside of pre-established parameters, and provide for remote-controlled shutdown of pump

stations on the pipelines. Pump stations and meter-measurement points along our pipelines are linked by satellite or telephone

communication systems for remote monitoring and control, which reduces the requirement for full-time on-site personnel at

most of these locations.