Sunoco 2013 Annual Report Download - page 11

Download and view the complete annual report

Please find page 11 of the 2013 Sunoco annual report below. You can navigate through the pages in the report by either clicking on the pages listed below, or by using the keyword search tool below to find specific information within the annual report.

9

The Nederland Terminal can deliver crude oil and other petroleum products via pipeline, barge, ship, rail, or truck. In

total, the terminal is capable of delivering over 2 million bpd of crude oil to our Crude Oil Pipelines or a number of third-party

pipelines including:

• the ExxonMobil pipeline to its Beaumont, Texas refinery;

• the DOE pipelines to the Big Hill and West Hackberry Strategic Petroleum Reserve caverns;

• the Valero pipeline to its Port Arthur, Texas refinery; and

• the Total pipelines to its Port Arthur, Texas refinery.

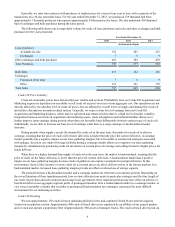

The table below summarizes the total average daily throughput for the Nederland Terminal in each of the years presented:

Year Ended December 31,

2013 2012 2011

Crude oil and refined products throughput (thousands of bpd) 932 724 757

Revenues are generated at the Nederland Terminal primarily by providing term or spot storage services and throughput

capabilities to a number of customers.

Fort Mifflin Terminal Complex

The Fort Mifflin Terminal Complex is located on the Delaware River in Philadelphia and includes the Fort Mifflin

Terminal, the Hog Island Wharf, the Darby Creek tank farm and connecting pipelines. Revenues are generated at the Fort

Mifflin Terminal Complex by charging fees based on throughput. In connection with Sunoco's decision to exit the refining

business, we recognized a charge in the fourth quarter 2011 related to the Fort Mifflin Terminal Complex for asset write-downs

and regulatory obligations which would have been incurred if certain terminal assets were permanently idled, as substantially

all of the revenues from the Fort Mifflin Terminal Complex are derived from the Philadelphia refinery. In September 2012,

Sunoco completed the formation of Philadelphia Energy Solutions ("PES"), a joint venture with The Carlyle Group, which

enabled the Philadelphia refinery to continue operating. In connection with this transaction, we entered into a new 10-year

agreement to provide terminalling services to PES at the Fort Mifflin Terminal Complex. In addition, we reversed certain

regulatory obligations that were no longer expected to be incurred as a result of the formation of PES.

The Fort Mifflin Terminal contains two ship docks with 40-foot freshwater drafts and a total storage capacity of

approximately 570 thousand barrels. Crude oil and some refined products enter the Fort Mifflin Terminal primarily from

marine vessels on the Delaware River. One Fort Mifflin dock is designed to handle crude oil from very large crude carrier-class

("VLCC") tankers and smaller crude oil vessels. The other dock can accommodate only smaller crude oil vessels.

The Hog Island Wharf is located next to the Fort Mifflin Terminal on the Delaware River and receives crude oil via two

ship docks, one of which can accommodate crude oil tankers and smaller crude oil vessels, and the other of which can

accommodate some smaller crude oil vessels.

The Darby Creek tank farm is a primary crude oil storage terminal for the Philadelphia refinery. This facility has a total

storage capacity of approximately 3 million barrels. Darby Creek receives crude oil from the Fort Mifflin Terminal and Hog

Island Wharf via our pipelines. The tank farm then stores the crude oil and transports it to the Philadelphia refinery via our

pipelines.

The table below summarizes the average daily number of barrels of crude oil and refined products delivered to the

Philadelphia refinery from the Fort Mifflin Terminal Complex in each of the years presented:

Year Ended December 31,

2013 2012 2011

(in thousands of bpd)

Crude oil throughput 258 293 267

Refined products throughput — 13 9

Total 258 306 276

Marcus Hook Tank Farm

The Marcus Hook tank farm has a total refined products storage capacity of approximately 2 million barrels. The tank

farm historically served Sunoco's Marcus Hook refinery and generated revenue from the related throughput and storage. In

2012, the main processing units at the refinery were idled in connection with Sunoco's exit from its refining business. The

terminal continues to receive and deliver refined products via pipeline and now primarily provides terminalling services to

support movements on our refined products pipelines.