BP 2010 Annual Report Download - page 71

Download and view the complete annual report

Please find page 71 of the 2010 BP annual report below. You can navigate through the pages in the report by either clicking on the pages listed below, or by using the keyword search tool below to find specific information within the annual report.

Businessreview

Business review

Operating management system

In2008,welaunchedOMS,ourgroup-wideframeworktodrivearigourous

andsystematicapproachtosafety,riskmanagement,andoperational

integrityacrossthecompany.OMSintegratesallrequirementsregarding

health,safety,security,environmentandoperationalreliability,aswellas

relatedissuessuchasmaintenance,contractorrelationsandorganizational

learning,intoacommonsystem.

TheprinciplesandstandardsofOMSaresupportedbydetailed

companypractices,aswellasothertechnicalguidancematerials.OMS

mandatesthatcertainstandards,group-denedpracticesandgroup

engineeringtechnicalpracticesbeimplementedcompany-wide;these

include,amongothers,theassessment,prioritizationandmanagementof

risk;incidentinvestigation;integritymanagement;andenvironmentaland

socialrequirementsformajornewprojects.

TheOMSincludestheseessentialrequirements,specically

addressingcrisisandcontinuitymanagementandemergencyresponse:

• Identifycrisisandcontinuitymanagementscenariosutilisingtheentity

riskregister,theoutputoftheentity’smajoraccidentriskassessment

andotherinformation.

• Implementandmaintaincrisisandcontinuitymanagementplansto

managethescenariosidentied.Thesewillincludeproceduresfrom

initiationtoresponseandrecovery.Atsiteleveltheseplansshall

includearrangementsforevacuationand,whereneeded,forinitial

shelter-in-place.

• Validatetheplansthroughexercisingthematdenedintervals.

Reviewtheplansatleastannuallytoreectchangesinhazards,risks,

organizationorcontactdetails,andimplementidentiedimprovements.

• Provideaccesstotrainedpersonnel,resources,medicalemergency

andotherfacilitiesneededtoimplementandexecutethecrisisand

continuitymanagementplans.

• Implement,maintainandexerciseadocumentedprocessfor

accountingforpersonnelduringandafteranemergencyevacuation.

OMSdenestheprocessforBPbusinessunitstoimplementthesystem

andcontinuouslyimprovetheiroperationalperformanceinallareas,

includingsafety.Theembeddingofacomprehensivemanagementsystem

suchasOMSacrossaglobalcompanyisamulti-yearprocess.

ThetransitiontoOMSrequireseachoperationtodevelopalocal

OMS(LOMS)thatdescribeshowtheoperationaddressessite-specic

localoperatingriskstomeetgroupstandardsandpracticesandcomply

withapplicableHSSElegalrequirements,whilefocusingontheirspecic

activities.AsanessentialstepindevelopingitsLOMS,thebusinessunit

conductsanassessmentofthegapsbetweenthestandardsandpractices

containedinOMSandthebusinessunit’slocalprocessesandprocedures,

andthendevelopsagap-closureplan.Everyyear,aftertheinitialgap

assessment,eachbusinessunitconductsanotherassessmenttoidentify

theadditionalstepstobetakentoimproveperformance.

ToformallytransitiontoOMS,anoperationissuesahandbookfor

theworkforcetofollow,completesamanagement-of-changedocument

thatdetailsthechangesinvolved,andobtainsformalsign-offbythe

segmentoperatingauthorityandbusinessunitleader.AllofBP’smajor

operationshadtransitionedtoOMSbytheendof2010,withtheremaining

oneregionallogisticsoperationcompletingtheprocessbytheendof

February2011.

BPwillcontinuetoevolveOMS,incorporatingimplementation

experienceaswellaslearningsfromincidentinvestigations,auditsandrisk

assessments,andbystrengtheningmandatorypractices.

GulfofMexicoincidentandtheOMS

TheGulfofMexicooperationscompletedtheirtransitiontoOMSin

December2009andnowcontinuetoworktowardsfullconformanceto

theOMS.RecommendationsfromBP’sinternalinvestigationintothe

DeepwaterHorizonincidentwillbeimplementedwithinourgroup-wide

OMSframeworkwhereappropriate;thisincludesupdatesaround

contractormanagementandoilspillpreparednessandresponse.Oncethe

externalinvestigationshaveproducedtheirndings,wewillcarryouta

reviewontheOMSframework;thisisexpectedtobecompletedinthe

thirdquarterof2011.SeeSubsequentactionstodateonpage68for

informationaboutourimmediateactivitiestofurtherstrengthenouroilspill

prevention,containmentandresponsecapability.

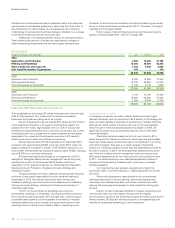

Processsafetymanagement

Processsafetyinvolvesapplyinggooddesignprinciples,alongwithrobust

engineering,operatingandmaintenancepractices,tomanagingoperations

safely.ForBP,thismeansensuringtheplantisdesigned,maintainedand

operatedproperlytoavoidfailuressuchasspillsorexplosionsthatcan

resultininjuriesandimpactstotheenvironment.

InSeptember2010,BPpublishedDeepwater Horizon Containment

and Response: Harnessing Capabilities and Lessons Learned,areport

sharedwiththeUSBureauofOceanEnergyManagement,Regulationand

Enforcement.Theselearningsareintendedtobenetourownoperations

andpotentiallythoseofourpeers,incaseofafutureincident.

ThereportidentiesfourbroadlessonsfromtheDeepwater

Horizonincident:

• C ollaboration:abroadrangeofstakeholderscametogetherinthewake

oftheDeepwaterHorizonincidenttoprovideeffectivesolutionsand

buildnewcapabilities.Itwouldhavebeenextremelydifcultforany

onecompanyalonetoaddresschallengesonthescaleofthe

DeepwaterHorizonincident.Theresponsebenetedfromclose

collaborationwithandthecapabilitiesoftheUSCoastGuard,Bureauof

OceanEnergyManagement,RegulationandEnforcementanddozens

ofotherpartnersandstakeholdersfromgovernment,industry,

academiaandtheaffectedcommunities,aswellasaroundtheglobe.

• Systemization:theresponsetotheincidentrequiredthedevelopment

ofextensivesystems,proceduresandorganizationalcapabilitiesto

adapttochanginganduniqueconditions.AstheDeepwaterHorizon

spillcontinueddespiteeffortsatthewellhead,theresponseeffort

progressed,expanded,andtookonnotjustnewtasksanddirections

butnewpersonnelandresources.Asaresult,fromsourcetoshore,

existingsystemswereevolvedandexpandedandnewonesdeveloped

toadvanceworkow,improveco-ordination,focuseffortsandmanage

risks.Theadoptionofthesesystemswillensuretheabilitytorespond

tofuturespillsmorerapidlyatscalewithacleardirectionasto

personnel,resourceandorganizationalneeds.

• Information:timelyandreliableinformationwasessentialacrossboth

thecontainmentandresponseoperationstoachievebetterdecision-

making,ensuresafeoperationsandinformstakeholdersandthepublic.

• Innovation:theurgencyincontainingthespillanddealingwithits

effectsdroveinnovationsintools,equipment,processesand

know-how,rangingfromincrementalenhancementstostepchangesin

technologiesandtechniques,thathaveadvancedthestateoftheart

andlaidthefoundationforfuturerenementsaspartofanenhanced

regimeforanytypeofsource-to-shoreresponse.

BPjoinedtheMarineWellContainmentCompany(MWCC),anon-prot

initiativewithExxonMobil,Shell,ConocoPhillipsandChevrondesignedto

quicklydeployeffectiveequipmentincaseofanotherunderwaterblowout

intheUSGulfofMexico.Thewellcontainmentequipmentusedinthe

DeepwaterHorizonresponsewillpreserveexistingcapabilityforusebythe

oilandgasindustryintheUSGulfofMexicowhiletheMWCCmember

companiesbuildasystemthatexceedscurrentresponsecapabilities.BP

hasalsoofferedtomakeavailabletotheMWCCBPtechnicalpersonnel

withexperiencefromtheDeepwaterHorizonresponse.

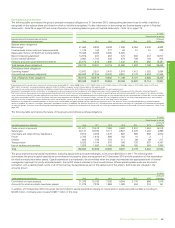

Oilspillsandlossofcontainment

Westrivetopreventfutureoilspillsbyweavingprocesssafetyintoevery

stageofthedesign,operationandmanagementofouroperations.We

monitortheintegrityofallouroperations,vesselsandpipelinesusedto

produce,processandtransportoilandotherhydrocarbons–withtheaim

ofpreventinganylossofhydrocarbonsfromtheirprimarycontainment.

Accordingly,werecordalllossesofcontainment,lossesofhydrocarbons

fromourassets(whichwemonitorasanenduringindicatorofprocess

safety),andlossesorspillsthatreachlandorwater.

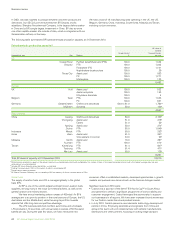

Thelossofprimarycontainmentmetricbelowincludesany

unplannedoruncontrolledreleaseofmaterial,excludingnon-hazardous

releasessuchaswater,fromatank,vessel,pipe,railcarorequipment

usedforcontainmentortransfer.

BPAnnualReportandForm20-F2010 69