Harley Davidson 2010 Annual Report Download - page 12

Download and view the complete annual report

Please find page 12 of the 2010 Harley Davidson annual report below. You can navigate through the pages in the report by either clicking on the pages listed below, or by using the keyword search tool below to find specific information within the annual report.

20 Customer-led Manufacturing

What’s an example of that?

Karl Our best-practice circles. They’re a huge part of

bringing the art and science of motorcycle manufacturing

together in a consistent way. These are groups of hourly

and salaried employees from multiple locations, as well

as outside suppliers, sharing specialized knowledge

around a common process. We have many best-practice

circles, in areas like safety, fabrication and machining.

Our best-practice circle in paint, for instance, has delivered

some unique combinations of paint and graphics that

create incredible nishes. In collaboration with suppliers,

they engineered a unique automated washing system that

ensures parts are contaminate free prior to painting.

And they have developed multiple ways to reduce paint

waste by 25 percent.

Matt I’d add continuous improvement. For us, it’s a

cultural movement to get every employee involved in

improving everything about us, from marketing to

product development to working closely with our

dealers. Continuous improvement drives consistency

and efciency in how we do our work. It adds value

to our products and services by making us more exible

and responsive to customers. And it’s real

—

we’re

teaching it in all of our plants, in exactly the same way,

so that everyone there works to make the operating

oor better.

What differences are customers going to see?

Matt We’re lucky enough to be in the business of

manufacturing dreams. And now, we have much better

insight into those dreams and much better processes to

tie that in to manufacturing. So they’ll see more relevant

innovation, better inventory availability, more

customization of motorcycles

—

like the factory custom

concept in H-D1

—

and more “wow” in styling and

features, because we’re listening in product development

and responding in our manufacturing. Consumers today

want what they want, how they want it, when they want

it. “Customer-led” is about making the right products

—

more-focused products

—

more responsively.

21

“ Consumers today want what

they want, how they want it,

when they want it.”

Matt Levatich

President & COO

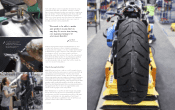

One way in which our manufacturing facilities are implementing common standards

is through Best Practice Circles (far right, bottom). The Paint Best Practice Circle,

comprised of hourly and salaried employees across our facilities, has implemented

continuous improvement solutions that have reduced paint waste by 25 percent.

Harley-Davidson, Inc. 2010 Annual Report