Harley Davidson 2010 Annual Report Download - page 11

Download and view the complete annual report

Please find page 11 of the 2010 Harley Davidson annual report below. You can navigate through the pages in the report by either clicking on the pages listed below, or by using the keyword search tool below to find specific information within the annual report.

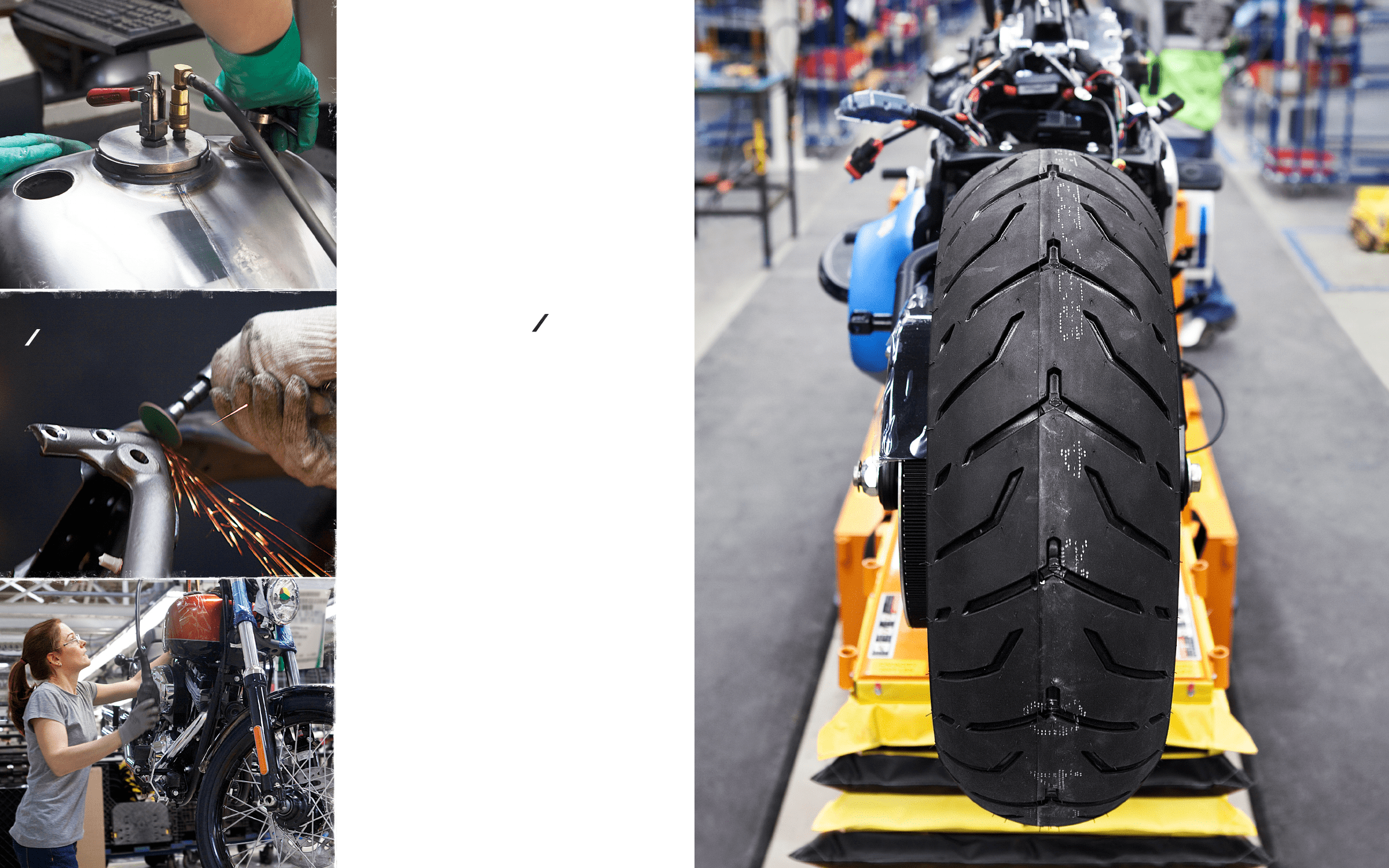

As our York facility continues

to transform, employees’

enhanced sense of accountability

gives them an even greater

customer-led mind-set.

“ We need to be able to make

any product on any line on

any day. So we’re structuring

our manufacturing to be

a lot more exible.”

Karl Eberle

SVP, Manufacturing

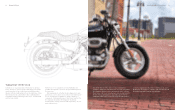

1918 Customer-led Manufacturing

Now, individuals can be responsible for more than one

task on more than one style of bike. And the assembly

line is being redesigned so that every part has a consistent

place in the line

—

wheels, handlebars, powertrain, tank and

the rest, all assembled in the same familiar sequence.

There was a lot of anxiety over the change, but employees

there will tell you they absolutely feel a new sense of

freedom, initiative and accountability.

Some of the obvious benets of commonality are cost

savings and efciency

—

there’s simpler management

of spare parts, for example, as well as standardized training

of maintenance people, engineers and technicians across

the factories so that, as we move people and share

knowledge across the factories, they see the same process

they did in the other factory. It’s an advantage in product

development, too, because our engineers know they

can design fenders and gas tanks that will be made the

same way at any two factories.

What do the results look like?

Matt When we get there

—

and we’re still a couple of years

away from having the new processes and systems fully up

and running in all of our plants

—

we’ll be able to shift

production between lines, change the level of output and

change our product mix in response to changes in customer

buying patterns and preferences. We’ll have a more rened

view of our production planning, rather than having to make

product supply predictions months ahead like we do now.

That’s the most important point from a customer perspective

—

the opportunity that we have to supply motorcycles

closer to when people want to buy them.

Karl Bottom line, we need to be able to make any product

on any line on any day. So we’re structuring our capital

investments to enable our manufacturing to be a lot more

exible

—

and making sure our employees have broad

expertise and diverse capabilities, too, so that they can

perform a much wider range of functions.

/ continued

Harley-Davidson, Inc. 2010 Annual Report