Harley Davidson 2010 Annual Report Download - page 10

Download and view the complete annual report

Please find page 10 of the 2010 Harley Davidson annual report below. You can navigate through the pages in the report by either clicking on the pages listed below, or by using the keyword search tool below to find specific information within the annual report.

So what’s actually happening to become customer-led

in manufacturing?

Matt In the last 18 months, we’ve moved on a lot of fronts.

There’s transformation in our plants, culture and

workforce. The opportunity is bigger than any one plant,

too. Being customer-led in manufacturing is leading us

toward a common build process, with standard sequences

and standard equipment wherever you go across our

factories. It’s unprecedented for us.

Karl We have four plants and 300 direct suppliers who

we need to have on board in this transformation.

There are work systems that need to be “rewired,” new

labor agreements that need to be implemented to enable

these changes, and employees who need to be retrained

so that they have greater expertise at more things. We’ve

had cooperation and success in all those areas.

Our York plant was the rst location to take on the

transformation, and what’s happening there will give

you a pretty good picture of the future. We’re going from

a 1.5 million-square-foot factory to 650,000 square feet,

and consolidating our footprint into one building. We are

focusing in-house on the core activities of paint, assembly

and metal fabrication

—

all the things we excel at and

that make the plant better than the competition. Part of

our workforce will consist of exible workers who we

can deploy depending on production needs. We reduced

the number of job classications from 62 to ve and in

the process are removing boundaries to work assignments.

/ continued

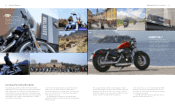

Matt It’s one part philosophy and one part discipline.

It’s knowing what our customers value

—

and don’t value

—

in our products and acting on that. Even though most of

us are riders, we can’t be satised with just our own

knowledge or the way we have always done things. We’re

doing more than ever to have the right conversations

with our customers and get their voice in the up-front

product development work. Then we’ve got to make sure

our production systems can deliver on that product

promise by getting the right bike to the right customer at

the right time. The motorcycle business is a seasonal

business, and a manufacturing model like we’ve had until

now

—

one that’s built for constant, level production

—

can’t

respond well to changes in demand or customer needs.

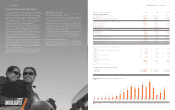

Karl And that’s meant a change for us, across the board.

You’ve got to remember that manufacturing processes in

any business are designed to make the same thing every

day, year-round. Doing that provides a certain level of

productivity and predictability for us and our suppliers

and employees who are skilled at certain things. But in

today’s world, that system is not nearly as agile in terms

of dialing production up and down when we need to.

And it’s not an efcient way to support the sales channel

and dealer network, either.

Matt So we needed to swallow hard and step away

from a manufacturing approach that worked for us

when demand outpaced supply, but wasn’t very exible.

With our historical manufacturing model, we were

producing motorcycles in the fall that probably wouldn’t

have been sold until the spring. And that forced

us to make three bets on the future: how many bikes to

produce; which models to produce; and where those

motorcycles were going to be sold at retail as we shipped

them to our dealers. We expect our new production

system to alleviate these issues.

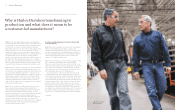

Q&A with Matt Levatich, President & Chief Operating Ofcer, and Karl Eberle, Senior Vice President, Manufacturing, Harley-Davidson Motor Company

Why is Harley-Davidson transforming its

production and what does it mean to be

a customer-led manufacturer?

16 Customer-led Manufacturing 17Harley-Davidson, Inc. 2010 Annual Report

Matt Levatich (left)

and Karl Eberle