Caterpillar 2011 Annual Report Download - page 11

Download and view the complete annual report

Please find page 11 of the 2011 Caterpillar annual report below. You can navigate through the pages in the report by either clicking on the pages listed below, or by using the keyword search tool below to find specific information within the annual report.

Construction Industries 11

WHAT THE WORLD NEEDS | 2011 YEAR IN REVIEW

Chairman’s

Message

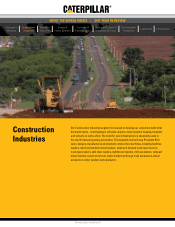

Construction

Industries

Customer &

Dealer Support

Financial Products &

Corporate Services

The Caterpillar

Foundation Leadership Performance

Resource

Industries

Energy &

Power Systems

Iron ore is used to make everything from steel products for

construction to utensils for eating. It is so commonplace that

many believe iron ore to be the most important global commodity

after oil. To keep up with global demand for this essential material,

companies often have to establish worksites in remote areas

with no developed infrastructure.

The mountainous jungle of Sierra Leone is a place not many

companies have ventured. When African Minerals Limited (AML)

decided to develop an iron ore mine in Tonkolili, a district in the

Northern Province of Sierra Leone, it quickly became apparent

that a 125-mile railroad would be needed to connect the mine to

the nearest port. AML commissioned WBHO, a civil contractor

based in South Africa, to build the railroad, and Caterpillar became

the sole equipment provider for this formidable project.

Challenges were plenty. The Tonkolili project was slated to begin

active mining in just 12 months, and of those, four months were

during Sierra Leone’s rainy season. The dense jungle and

mountainous region created topographical issues since railroads

cannot be built with more than a 4 percent ascending grade. The

aggressive timeline and challenging terrain meant jobsite efficiency

and machine performance were of the utmost importance.

Caterpillar developed a plan for WBHO to purchase and rent

equipment through Mantrac, the Cat® dealer in West Africa.

Of a total fleet of 1,608 mobile plant items, Caterpillar supplied

412 machines and 20 power generation units. In addition, a

Caterpillar applications specialist worked closely with WBHO to

ensure machines were working efficiently to keep productivity

at the highest level. Articulated truck drivers, for example, were

given special training in order to operate fully loaded trucks

on steep grades so as not to damage the brakes. Caterpillar’s

complete presence at Tonkolili paid off. WBHO moved a stag-

gering six million cubic meters of earth and constructed the

railroad successfully within the 12-month timetable.

Caterpillar’s support also reached the local population, who were

in need of jobs after years of war and hardship. The training

that local residents received from Caterpillar specialists has

provided life skills that can be used long after the railroad has

been commissioned. The now accessible mine provides thousands

of jobs, not only helping satisfy the world’s need for iron ore, but

also Sierra Leone’s citizens’ need for a better livelihood.

Moving

Mountains

That’s what it takes to build a

mission-critical railroad through the

challenging terrain of Sierra Leone.

6 Million M3

WBHO moved a staggering six million

cubic meters of earth and constructed

the railroad successfully within the

12-month timetable.