BMW 2009 Annual Report Download - page 40

Download and view the complete annual report

Please find page 40 of the 2009 BMW annual report below. You can navigate through the pages in the report by either clicking on the pages listed below, or by using the keyword search tool below to find specific information within the annual report.

38

12 Group Management Report

12 A Review of the Financial Year

14 General Economic Environment

18 Review of Operations

42

BMW Group – Capital Market

Activities

45 Disclosures pursuant to § 289 (4)

and § 315 (4) HGB

48 Financial Analysis

48 Internal Management System

50 Earnings Performance

52 Financial Position

54 Net Assets Position

56 Subsequent Events Report

56 Value Added Statement

58 Key Performance Figures

59 Comments on BMW AG

63 Internal Control System

64 Risk Management

70 Outlook

Further improvements in profitability along the

value-added chain

Our main focus with regard to the purchasing and supplier

network in 2009 was to continue the previous year’s ini-

tiative

of creating the most efficient value-added chain in

the automotive industry.

Working closely with our suppliers, we made further

progress in reducing the cost of materials for

vehicle

projects both in the development and series production

stages. Particular attention was paid to maintaining

the high

level of quality expected by our customers. The

purchasing department was supported in this process

by the development team, particularly in its consistent

application of modular solutions. The increased use of

standardised components enables both time and costs

to be reduced across all models. Important milestones

were therefore set in 2009 with regards to the future pur-

chasing arrangements for the BMW 1 and 3 Series suc-

cessor models.

Parts supply assured despite difficult market

environment

The consequences of the worldwide financial and eco-

nomic

crisis particularly affected the automotive supply in-

dustry during the year under report. Declining production

volumes coupled with simultaneously decreasing liquidity

levels and rising financing costs had a significant impact

on the financial stability of the supplier market, resulting in

a greater incidence of crisis situations among suppliers at

a national and international level. However, a consistent

strategy of risk and intervention management enabled the

various crises to be successfully mastered without having

a lasting detrimental effect on supply security or car pro-

duction quality.

Increasing internationalisation of the purchasing

network

We continued to expand our international purchasing

n e t

work with great determination in 2009. By concentrating

on

the Asian and NAFTA regions for new purchase vol-

umes, we were able to make optimal use of cost advan-

tages, while also expanding the scope of so-called “natural

hedging” – the strategy of purchasing in foreign curren-

cies

to minimise exchange risks. With this in mind, re-

gional experts

with a good understanding of purchasing,

quality and logistics issues analyse the various procure-

ment

markets and suppliers in close cooperation with

cen-

tralised management functions. This strategy will enable

us to achieve cost and currency benefits on purchases for

future models. The basis for this was laid in 2009 with the

selection of suppliers for the BMW 1 Series and 3 Series

models.

Future natural hedging volumes are also increased by

placing multi-currency orders (i. e. purchasing individual

components in varying currency proportions) – a practise

we have employed since 2009.

Innovation and technology leadership of BMW

in-house component production maintained

In the fields of bodywork and interiors, our components

plant in Landshut again demonstrated its innovative and

technological

leadership. At the European

SPE

Auto-

motive Division Award competition held in 2009, the

International Plastics Society presented the highest

awards in the categories “Exterior” and “Interior” to the

BMW Group.

Our light metal foundry also confirmed its technological

leadership. We will be commissioning the world’s first

odourless foundry at our Landshut plant in 2010. The use

of environmentally sustainable binding agents will enable

us to reduce emissions from combustion residues by

98 %.

Greater emphasis on sustainability and innovation

in supplier market

Our stringent requirements for ecological and social

standards are increasingly being applied along the value-

added chains within the supplier network. Suppliers and

their partners must provide detailed proof of their

com-

pliance with the required standards for sustainability in

order to take part in the tendering procedure. As part

of the selection process, our experts check whether

pro-

spective suppliers are complying with the required

standards.

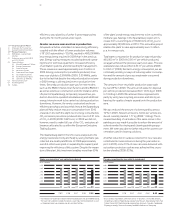

Regional mix of BMW Group purchase volumes 2009

in %, basis: production material

Germany 47 NAFTA 1 0

Rest of Western Europe 21 Asia / Australia 7

Central and Eastern Europe

12 Africa 3

Germany

Central and

Eastern Europe

Rest of Western Europe

NAFTA

Asia / Australia Africa