Atmos Energy 2015 Annual Report Download - page 8

Download and view the complete annual report

Please find page 8 of the 2015 Atmos Energy annual report below. You can navigate through the pages in the report by either clicking on the pages listed below, or by using the keyword search tool below to find specific information within the annual report.

12 13

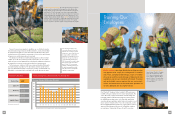

Our damage prevention efforts have yielded a steady

decline in damages to our pipeline systems. Since 2010, we

have reduced damages per 1,000 line locates by 11 percent.

That improvement is all the more impressive in light of the

economic development activities in our service areas that

have caused annual requests for facility-locates to rise by 24

percent since 2010 to more than 1.9 million annual requests.

Eliminating third-party damages requires vigilance and

diligence by our damage prevention specialists, who contact

repeat offenders to seek their cooperation to observe the

law and to protect their workers and the public.

An especially important part of our damage prevention

program is sponsoring training and meetings by our state

One-Call organizations to reach professional excavators.

We are a Gold Sponsor of the national Common Ground

Alliance and we are a strong ally with our states’ damage

prevention councils to promote safety.

Along with fewer damages, the number of active leaks on

our system has declined by 31 percent since 2010.

We continue to seek better leak detection technologies

as part of our comprehensive safety strategy. Innovative

gas-analysis instruments, involving mass spectroscopy, are

approximately 1,000 times more sensitive than traditional

leak detection equipment and are capable of sensing gas

leaks down to one part per billion in ambient air while

reducing false positives from naturally occurring methane.

We are conducting tests with this equipment mounted in

a vehicle to determine whether the technology can measure

and monitor methane levels from gas pipeline leaks, as

compared to methane emissions from countless other

sources, such as farm animals, vehicles and pollution.

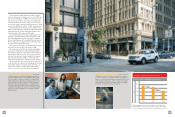

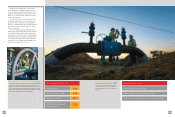

In the center of downtown Dallas, Atmos Energy

is testing an advanced leak detection technology that is much more

sensitive for identifying methane releases than conventional methods.

The instrumentation is installed in a standard SUV, making it highly

mobile and allowing sampling to occur at driving speeds. The tech-

nician driving the vehicle also is informed in real time of potential

leaks that can be investigated promptly. Right: Brandon Nelson,

a compliance specialist in the Mid-Tex Division, and Tamera Hewitt,

a geographic information system specialist in the division, evaluate

maps from a survey to help identify areas needing closer attention

for potential leaks.

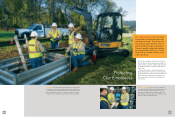

An existing natural gas pipeline (below) is located by

Jeff Knight, a crew leader in the Louisiana Division, in preparation

to install a new main to serve additional customers in Covington. Line

locators use colored flags and temporary spray paint to mark the routes

of all underground utility facilities, so that excavators know to dig only

by hand within tolerance zones around the buried lines. Line-locating

of utility lines is provided to the public free of charge.

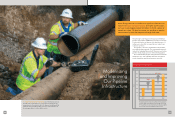

Targeted Infrastructure Replacement

Replacing aging pipeline infrastructure and service lines helps reduce

potential leaks on our system. Since fiscal 2010, we have replaced nearly

1,000 miles of pipelines. We plan to double our replacements by fiscal 2020.

8,000

6,000

4,000

2,000

0

Miles

Bare Steel, Cast Iron and Early Generation Plastic

2010 2015 2020

975

1,950