Atmos Energy 2015 Annual Report Download - page 3

Download and view the complete annual report

Please find page 3 of the 2015 Atmos Energy annual report below. You can navigate through the pages in the report by either clicking on the pages listed below, or by using the keyword search tool below to find specific information within the annual report.

3

Atmos Energy’s natural gas transmission and distribution

pipelines span almost 76,000 miles and range in size from

2 inches to 36 inches in diameter. We also have some 3.1

million service lines that carry gas from our mains to our

customers’ premises.

Our pipelines, which were installed over many decades,

are made of various materials. The most common types are

coated steel and polyethylene plastic. However, we also have

pipelines made of cast iron, bare steel and vintage plastic.

Our modernization program along with federal and state

compliance rules and regulations determine the pipeline

assets selected for repair or replacement every year.

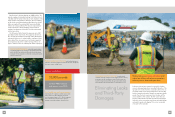

Modernizing

and Improving

Our Pipeline

Infrastructure

2

Atmos Energy continues to modernize its pipeline infrastructure to

make it even safer and more reliable. During the past five years,

we have invested approximately

$4.0 billion to fortify, replace or

expand our system. We plan to increase our spending on pipeline

modernization by more than 50 percent through fiscal 2020.

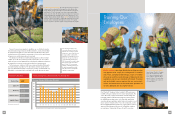

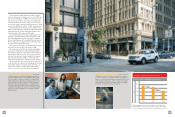

During the past five years, the number of miles of pipeline

we have replaced annually has increased by 120 percent.

We expect that our annual replacements will go up another

25 percent to 30 percent during the next five years.

600

500

400

300

200

100

0

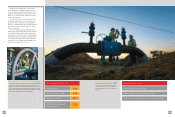

2010 2015 2020

Miles

Distribution Main Annual Replacement Mileage

12 0 %

25%–30%

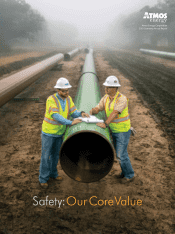

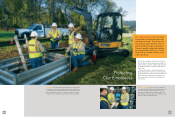

A major replacement project in our West Texas Division near

Amarillo involves constructing a new 16-inch coated steel pipeline to retire

an aging bare steel line installed in the 1930s. Engineer Matt McDonald (left)

and Dustin Crosley, Amarillo operations supervisor, test the wall thickness of

the existing pipe before it is tied in with the new line.

Investing in Infrastructure