Atmos Energy 2015 Annual Report Download - page 7

Download and view the complete annual report

Please find page 7 of the 2015 Atmos Energy annual report below. You can navigate through the pages in the report by either clicking on the pages listed below, or by using the keyword search tool below to find specific information within the annual report.

10 11

Equally critical is driving safety for our 4,000 vehicles. We

provide employees training for backing, Smith System driver’s

education and first-person videos by our own employees who

impart lessons learned to their colleagues. We are installing

on all vehicles new flashing lights to signal when the vehicle’s

brakes are applied; the warning lights have proved highly

effective at reducing collisions. We also are using inside our

vehicles DriveCam® video technology, which records an

employee’s performance behind the wheel for training and

accident prevention.

Our Enterprise Safety Committee sponsors some 220

operational safety-team leads. They organize safety hud-

dles at company locations and develop Safety Champions

who coach their peers. In safety huddles, employees share

stories about their own experiences to help our organiza-

tion improve based on the real-life learning of these em-

ployees and their inherent credibility with fellow employees.

Improved technologies, such as this remote methane

leak detector, help keep our employees safe while they protect the

public. An RMLD can quickly and efficiently detect a natural gas

leak up to 100 feet away and is used for leak surveying and respond-

ing to emergency calls.

Professional driver’s training and backing training are

part of our core learning program for all field technicians, who operate

some 4,000 vehicles in daily service.

Our health and wellness programs

have helped 3,900 employees and their spouses work

and live at their best by shedding 33,000 pounds

since the programs began in 2010. Besides improving

fitness and lowering medical insurance costs, our

programs encourage employees to avoid injuries.

Health and Wellness

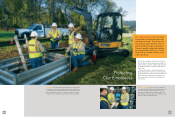

Leaks occur for various reasons, but one of the leading

causes is damage to pipelines caused by third parties. This

typically is the result of careless excavation, often when an

excavator violates state law by failing to have buried utility

facilities located and marked. Anyone excavating at depths

greater than the state requirement must, by law, call the

universal toll-free 811 number. The 811 Center then dis-

patches professional line locators to find all underground

utility lines in the area and to mark them with colored flags

and paint to guide safe digging. This service is provided

at no cost to the excavator.

33,000 pounds

lost by 3,900 employees

and spouses since 2010

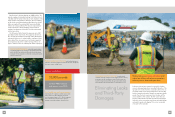

Damage prevention seminars for professional

excavators encourage calling 811 before digging and stress industry

best practices for safe excavation. In Austin, Texas, Texas811, the

Austin Fire Department and Atmos Energy demonstrated not only

how to dig safely, but also steps to take if a natural gas line is hit.

Eliminating Leaks

and Third-Party

Damages

Pipeline leaks are a primary safety focus of all

natural gas utilities, with extensive precautions

taken to prevent, detect and repair them.