Halliburton 2015 Annual Report Download - page 8

Download and view the complete annual report

Please find page 8 of the 2015 Halliburton annual report below. You can navigate through the pages in the report by either clicking on the pages listed below, or by using the keyword search tool below to find specific information within the annual report.Halliburton’s superior service quality and more efficient technology help our customers

unlock the value of their reserves by bending their cost curve, getting more from their

investment per barrel of oil equivalent. Reducing the cost per barrel requires focus on both

elements of the equation by reducing the numerator – improving efficiency and driving

lower operating costs – and increasing the denominator by improving well productivity

and estimated ultimate recovery.

Halliburton is a leader in the industry’s efforts to drive down costs at every step of drilling

and completion – optimizing bit designs, fluid compositions and well designs, in many cases

reducing drilling time by as much as 50 percent.

Well completion sizes continue to increase. For instance, the average sand volume per well

has doubled in just the last two years. We help our customers avoid disruption and reduce

costs through our world-class supply chain organization that manages Halliburton railcars, basin

inventory levels and well site sand deliveries in real time. We have reduced the time spent

waiting for sand by 70 percent. The cost to deliver a ton of proppant is the lowest it has been

in five years.

Bigger, more complex well completions put more strain on pumping equipment. Halliburton’s

Q10™ technology – the centerpiece of the Frac of the Future™ – enables us to do the same

quantity of work with 20 percent less capital on location and up to 45 percent less maintenance

cost. At year end, Frac of the Future™ spreads represented 60 percent of our fleet.

Surface efficiency helps operators drive down their costs. But customers are also focused

on better wells – identifying the best targets and using the right chemistry to produce more

barrels. Our belief is that for shale development – even within a single well – the rocks are

not the same. For Halliburton, that requires a focus on two high-level categories – sub-surface

insight to help identify the target zones and custom chemistry to help maximize the stimulated

rock volume.

Our DecisionSpace® Unconventionals software suite is designed to help improve well and

reservoir modeling and better predict technical and economic performance. Its dynamically-

updateable model supports E&P business processes to help reduce time for decision-making

and increase team collaboration.

MicroScoutSM Service, a recent addition to our custom chemistry portfolio, is a hydraulic

fracturing treatment designed to deliver proppant into far field microfractures, enhancing the

productive life of new wells. Early trials have indicated more than a 20 percent uplift in production

compared to offset wells.

Through the downturn, we have seen operators adopt these new solutions more quickly. After

years of efficiency improvements, it is our view that subsurface insight and custom chemistry

will drive the next leg in efficiency, helping our customers to further lower their cost per BOE

during the downturn as well as in the next upcycle. We believe Halliburton’s advantages in

North America – the largest oilfield service market in the world – will offer the greatest upside

in the recovery and propel Halliburton in the next phase of the cycle.

North America

Halliburton 2015 Annual Report

www.halliburton.com

6

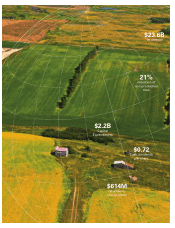

Cost per Barrel

Cost per barrel is a simple concept that underscores

our strategy in the unconventional fields of North

America. Reducing the cost per barrel of oil equivalent

(BOE) for our customers requires focusing on both

sides of the equation by reducing the numerator –

improving efficiency and driving lower operator

costs – and increasing the denominator by improving

well productivity and estimated ultimate recovery.