Chevron 2003 Annual Report Download - page 19

Download and view the complete annual report

Please find page 19 of the 2003 Chevron annual report below. You can navigate through the pages in the report by either clicking on the pages listed below, or by using the keyword search tool below to find specific information within the annual report.

17

Our technology group is working with Global Gas to commercialize our

very large natural gas resources. Liquefied natural gas (LNG) receiving

terminals, such as the one we are planning to construct offshore Louisiana

in the United States, will use advanced LNG unloading and transfer sys-

tems. Our activities in gas-to-liquids (GTL) technology include research

and development for next-generation conversion technology and step-out

technologies in GTL plants under construction.

Downstream, our El Segundo, California, refinery in the United States

is piloting proprietary reactor technology that improves catalyst life and

enhances reliability. The technology is expected to lower El Segundo’s

operating costs. The company expects to deploy this technology to other

reactors in its worldwide refinery system.

A PARTNER OF CHOICE Partnerships are an important part of Chevron-

Texaco’s approach to technology. Internally, our researchers work with

business units to improve current and future performance. Externally, our

partnerships are with academic, business and public-sector organizations.

These partnerships enable us to share technical risk, cost and talent with

others that have complementary capabilities.

Our partnerships with universities and other academic institutions have

long been an important and successful part of our research effort. Over

the last three years, we have established research centers at three U.S.

universities: University of Tulsa, Colorado School of Mines and University

of Southern California. These centers conduct research aimed at solving

actual problems that exist in our business today and provide the opportu-

nity for our employees to earn advanced degrees.

POSITIONING FOR THE FUTURE Our investments in energy tech-

nologies such as hydrogen and renewables position us to provide clean,

economically viable energy from hydrocarbons and alternate sources as

future markets develop and technical challenges are overcome.

We also are active in technologies such as advanced materials that will

improve our operational performance or become potential new sources

of revenue. Two key areas of research are hydrogen fuel and the rapidly

emerging field of nanotechnology. In 2003, the U.S. Department of Energy

awarded ChevronTexaco a grant to explore new fuel processing technology

based on hydrogen. The project will build a prototype fuel processor to

supply hydrogen from natural gas to fuel cells that produce electrical power

for businesses, homes and vehicles. In nanotechnology, we are producing a

series of new molecular building blocks, called diamondoids, from certain

petroleum resources. They could potentially be used for electronic materials,

specialty coatings, polymers and other advanced materials.

CONNECTED

BY TECHNOLOGY

A business focus guides our approach in the

fast-evolving information technology (IT)

area. Our IT global digital infrastructure was

completed in 2003, connecting 50,000 desk-

tops and 1,800 company locations. Going

forward, the project is expected to save

approximately $50 million per year by elimi-

nating duplicate processes and systems.

A global network enables online “real time”

collaboration across the world’s time zones.

When engineers face technical challenges,

they can tap into an online network to fi nd

solutions from colleagues anywhere in the

world who may have solved similar prob-

lems. This reduces downtime, duplicated

effort and associated costs.

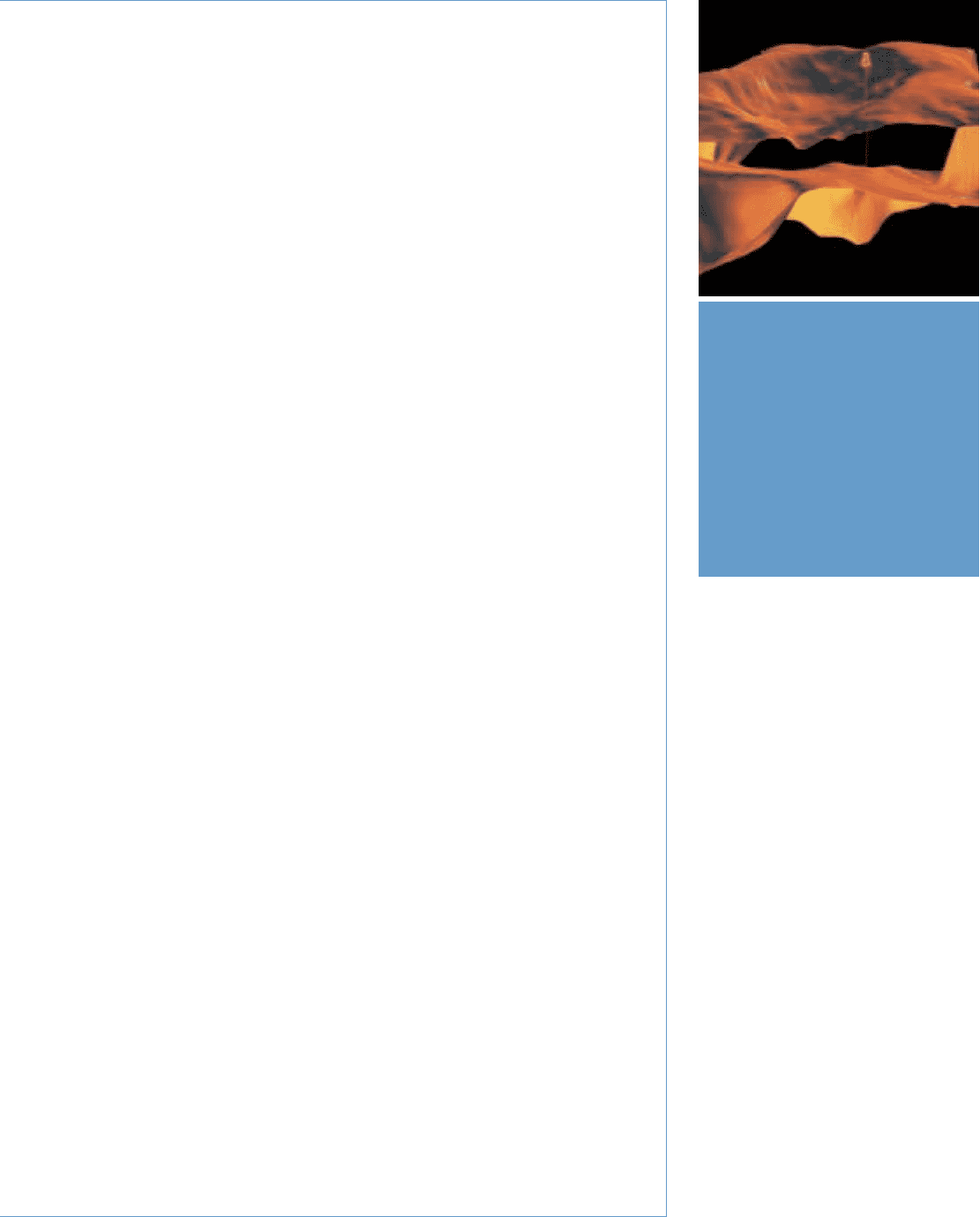

Our advanced proprietary imaging

technology enables us to visualize

the full extent of the Tahiti Field,

one of the largest crude oil and

natural gas reservoirs discovered

to date in the U.S. Gulf of Mexico.

Such technologies are contributing

to our success in adding reserves

and resources through both explora-

tion and reservoir management.