Kia 2000 Annual Report Download - page 11

Download and view the complete annual report

Please find page 11 of the 2000 Kia annual report below. You can navigate through the pages in the report by either clicking on the pages listed below, or by using the keyword search tool below to find specific information within the annual report.

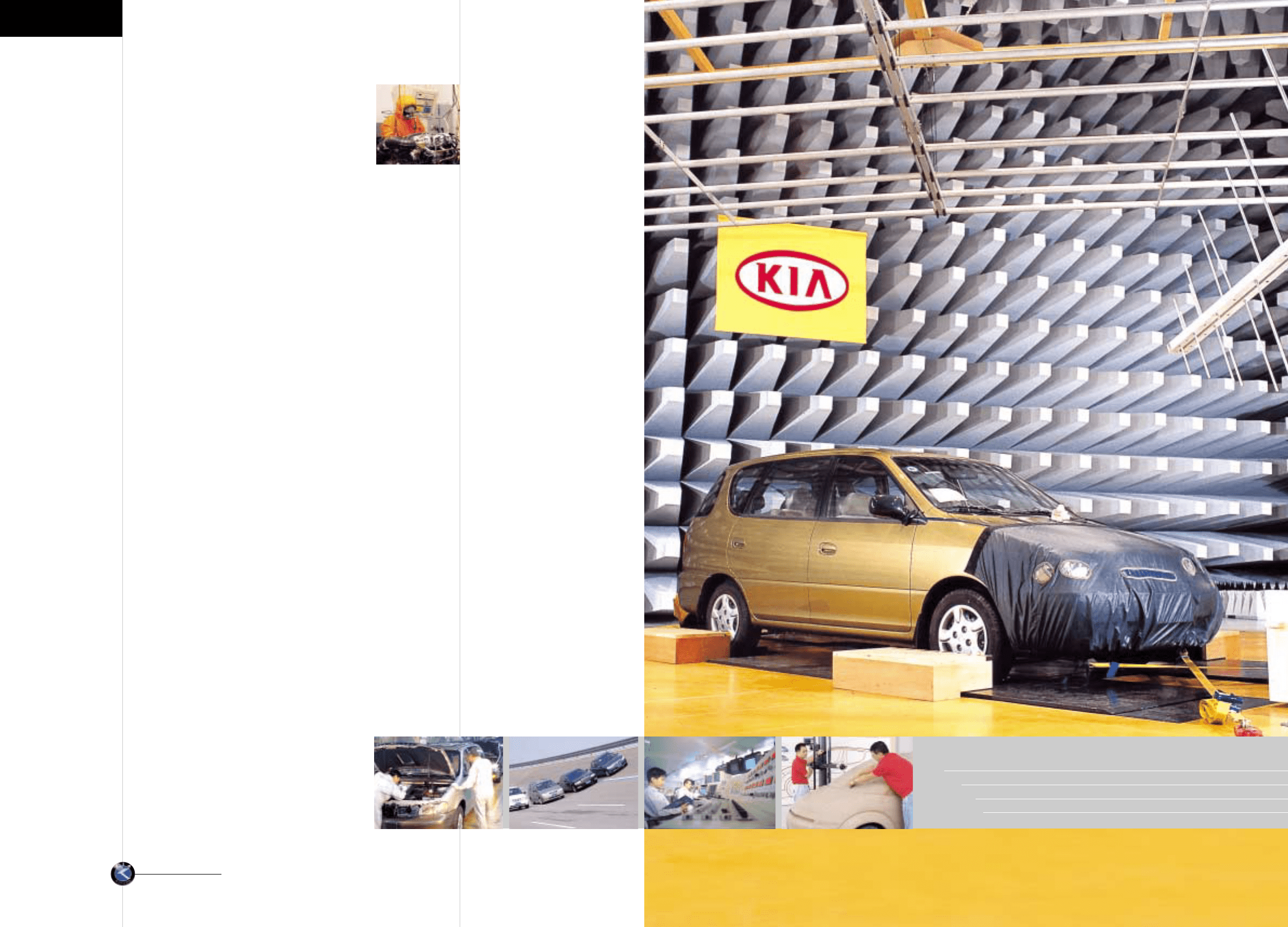

Recently, Kia has been carrying out radical reforms in all production

facilities. We have maximized efficiency by conducting large-scale

reorganization and expansion of production lines according to their

individual characteristics. As a result, our finished automobile

division produced 803,000 units for a 14.7% increase over the

previous year.

In 2001, we plan to increase productivity a further 10% by

aggressively strengthening four key areas: reducing standard

production processes, increasing the straight line ratio, reducing

time between new model launches and improving logistics. Greater

efficiency at production sites will allow us to produce 968,000

vehicles this year in the finished car division, a 20.5% increase year

on year.

The full-scale implementation of Six Sigma coupled with

continuous improvement activities have improved finished car

quality while helping to raise productivity and lower costs. We have

designated 2001 as the First Year of Quality Management for the

Achievement of World-class Quality by 2005.Kia employees are

united in their determination to win the Korean Quality Grand

Prize,the most prestigious quality-related award in the nation.

In 1999, the Kia/Hyundai Integrated R&D Center first achieved a

maximum synergy effect through the joint use of platforms and

parts. For new product development, we began by rolling out the

Spectra in April. The Optima was unveiled in July, injecting new life

into the depressed mid-sized car market and also demonstrating

joint platform usage for the first time.

Kia launched the Spectra Wing in October, showing firm resolve

in the near-mid-sized market. By focusing on export model

development, Kia was able to roll out the Rio in May and the Optima

in October in North America. For the year, Kia completed

the development of 41 different models, including those for export.

Kia has conducted various seminars and other educational pro-

grams to hone researcher skills. As a result, Kia researchers devel-

oped 2.5-mile gain bumper technology for which Kia was awarded

the KT Mark. The academic activities of our researchers have

resulted in the publication of 11 theses, as well as the registration of

467 claims for industrial property rights.

In preparation for greater market competition in 2001, Kia is now

engaged in the final development efforts for 35 new vehicle models.

Moreover, profitability remains our top priority. Every Kia researcher

is also working to ensure basic cost planning is reflected in each

new model that comes out.

Kia has taken productivity and profitability to a higher level

by reorganizing production lines,

implementing Six Sigma and reducing production costs.

◀◀◀ Finished cars undergoing high-speed performance tests

◀◀ Quality control center

21st century, state-of-the-art engine R&D

◀◀◀◀ System of frequent inspections in action on the Carnival production line

◀Prototype of new model manufactured with state-of-the-art computers

2000 KIA MO TO RS

AN N UAL REPORT / 19-20

Production, quality, R&D