Energy Transfer 2015 Annual Report Download - page 11

Download and view the complete annual report

Please find page 11 of the 2015 Energy Transfer annual report below. You can navigate through the pages in the report by either clicking on the pages listed below, or by using the keyword search tool below to find specific information within the annual report.

Table of Contents

index price. In addition, our intrastate transportation and storage segment generates revenues from fees charged for storing customers’ working natural gas in

our storage facilities and from managing natural gas for our own account.

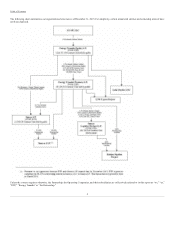

Interstate Transportation and Storage Segment

Natural gas transportation pipelines receive natural gas from other mainline transportation pipelines, storage facilities and gathering systems and deliver the

natural gas to industrial end-users, storage facilities, utilities and other pipelines. Through our interstate transportation and storage segment, we directly own

and operate approximately 12,300 miles of interstate natural gas pipelines with approximately 11.2 Bcf per day of transportation capacity and have a 50%

interest in the joint venture that owns the 185-mile Fayetteville Express pipeline and the 500 mile Midcontinent Express pipeline. ETP also owns a 50%

interest in Citrus, which owns 100% of FGT, an approximately 5,325 mile pipeline system that extends from south Texas through the Gulf Coast to south

Florida.

Our interstate transportation and storage segment includes Panhandle, which owns and operates a large natural gas open-access interstate pipeline

network. The pipeline network, consisting of the Panhandle, Trunkline and Sea Robin transmission systems, serves customers in the Midwest, Gulf Coast and

Midcontinent United States with a comprehensive array of transportation and storage services. In connection with its natural gas pipeline transmission and

storage systems, Panhandle has five natural gas storage fields located in Illinois, Kansas, Louisiana, Michigan and Oklahoma. Southwest Gas operates four of

these fields and Trunkline operates one.

We also own a 50% interest in the MEP pipeline system, which is operated by KMI, and has the capability to transport up to 1.8 Bcf/d of natural gas.

Gulf States is a small interstate pipeline that uses cost-based rates and terms and conditions of service for shippers wishing to secure capacity for interstate

transportation service. Rates charged are largely governed by long-term negotiated rate agreements.

We are currently in the process of converting a portion of the Trunkline gas pipeline to crude oil transportation.

The results from our interstate transportation and storage segment are primarily derived from the fees we earn from natural gas transportation and storage

services.

Midstream Segment

The midstream natural gas industry is the link between the exploration and production of natural gas and the delivery of its components to end-use markets.

The midstream industry consists of natural gas gathering, compression, treating, processing, storage, and transportation, and is generally characterized by

regional competition based on the proximity of gathering systems and processing plants to natural gas producing wells and the proximity of storage facilities

to production areas and end-use markets.

The natural gas gathering process begins with the drilling of wells into gas-bearing rock formations. Once a well has been completed, the well is connected to

a gathering system. Gathering systems generally consist of a network of small diameter pipelines and, if necessary, compression systems, that collects natural

gas from points near producing wells and transports it to larger pipelines for further transportation.

Gathering systems are operated at design pressures that will maximize the total throughput from all connected wells. Specifically, lower pressure gathering

systems allow wells, which produce at progressively lower field pressures as they age, to remain connected to gathering systems and to continue to produce

for longer periods of time. As the pressure of a well declines, it becomes increasingly difficult to deliver the remaining production in the ground against a

higher pressure that exists in the connecting gathering system. Field compression is typically used to lower the pressure of a gathering system. If field

compression is not installed, then the remaining production in the ground will not be produced because it cannot overcome the higher gathering system

pressure. In contrast, if field compression is installed, then a well can continue delivering production that otherwise might not be produced.

Natural gas has a varied composition depending on the field, the formation and the reservoir from which it is produced. Natural gas from certain formations is

higher in carbon dioxide, hydrogen sulfide or certain other contaminants. Treating plants remove carbon dioxide and hydrogen sulfide from natural gas to

ensure that it meets pipeline quality specifications.

Some natural gas produced by a well does not meet the pipeline quality specifications established by downstream pipelines or is not suitable for commercial

use and must be processed to remove the mixed NGL stream. In addition, some natural gas produced by a well, while not required to be processed, can be

processed to take advantage of favorable margins for NGLs extracted from the gas stream. Natural gas processing involves the separation of natural gas into

pipeline quality natural gas, or residue gas, and a mixed NGL stream.

5