Cemex 2009 Annual Report Download - page 12

Download and view the complete annual report

Please find page 12 of the 2009 Cemex annual report below. You can navigate through the pages in the report by either clicking on the pages listed below, or by using the keyword search tool below to find specific information within the annual report.

COMMITMENT

to address climate change

MOVING FORWARD

Our commitment to sustainable and responsible business

practices not only enables us to build a better world for

future generations, but also ensures our company’s long-

term competitiveness. As part of our global sustainability

strategy, we are undertaking a number of initiatives to

address the challenges posed by climate change.

We actively collaborate with stakeholders—inside and out-

side of our industry—to advance innovative ways to design,

construct, and operate more sustainable, energy-efficient

buildings. A prime example is our involvement in the World

Business Council for Sustainable Development (WBCSD).

Through our work with the WBCSD, we participated in the

three-year Energy Efficiency in Buildings initiative up to and

including the publication of its final report in April 2009.

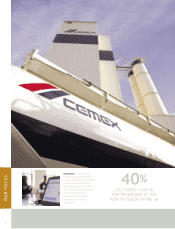

Among the findings of this joint effort, we determined that

buildings are responsible for as much as 40% of the energy

used in most countries, and approximately 88% of this

energy is consumed during their life span for operation,

maintenance, and renovation. That is precisely the area in

which our industry can make one of the biggest contribu-

tions: to develop ready-mix concrete products that help

save energy during the lifetime of a building. When properly

designed and constructed, concrete buildings can improve

energy efficiency and can last for decades with little or no

maintenance. Led by our Global Center for Technology and

Innovation in Switzerland, our research labs are working

every day to design and develop more sustainable build-

ing materials, such as our high-insulation concrete forms

that help keep heat out in hot climates and prevent it from

escaping in cold weather, thus saving energy. Moreover,

the improved strength and density of our self-compacting

concrete increase the life of a building and reduce its main-

tenance costs.

Additionally, we are on track to achieve our goal of a 25%

reduction in specific CO2 emissions by 2015 from 1990

levels. Indeed, in 2009 we achieved a 20.7% reduction in

our CO2 emissions. To this end, we continued to expand

our use of more economical, environmentally friendly al-

ternative fuels and renewable sources of energy. In 2009,

we completed the Eurus wind farm in Oaxaca, Mexico.

Jointly developed by CEMEX and ACCIONA Energía, Eu-

rus is one of the largest wind farms in the world and the

largest wind power generator in Latin America. With 167

wind turbines, each generating up to 1.5 megawatts (MW)

of power, the Eurus wind farm has a production capacity

of 250 MW of power and can supply approximately 25%

of our Mexican plants’ energy needs. Financed, con-

Active collaboration

Through our work with the

WBCSD, we participated

in the three-year Energy

Efciency in Buildings

initiative up to and including

the publication of its nal

report in April 2009.

structed, and managed by ACCIONA, the wind farm will

achieve the second largest reduction of CO2 emissions—

approximately 600 thousand metric tons each year—of

any project registered under the United Nations’ Clean

Development Mechanism.

Furthermore, we substantially increased our use of

alternative fuels from 10.3% of our cement plants’ total

energy consumption in 2008 to 16.4% in 2009—thus

saving the fossil fuel equivalent of one million tons of coal

and avoiding 1.2 million tons of CO2 emissions. In Europe,

our plants’ use of alternative fuels is even higher. Thanks

to our shared best practices, today, alternative fuels ac-

count for close to 70% of the total fuel consumption in

our Chelm cement plant in Poland. This plant primarily

uses refuse-derived fuel (RDF), obtained from specialized

waste management plants that collect, treat, and turn

municipal and commercial waste into a solid, safe fuel.

In the UK, regulators recently granted us permission to

work with a joint-venture partner to construct and operate

an RDF facility near our Rugby plant. In 2009 we replaced

more than 40% of fossil fuels, such as coal, with RDF and

tires at our Rugby plant, creating significant environmental

and sustainability benefits such as a marked reduction of

nitrogen oxide emissions.

At CEMEX, we acknowledge the global challenges posed

by climate change and are committed to applying our

ideas, our skills, our technologies, and our determina-

tion to engage in developing a pathway to a low-carbon

economy.

For more information about our sustainability strategy and

practices, please visit our website at www.cemex.com/

sustainability.

10