Sunoco 2008 Annual Report Download - page 19

Download and view the complete annual report

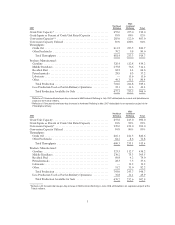

Please find page 19 of the 2008 Sunoco annual report below. You can navigate through the pages in the report by either clicking on the pages listed below, or by using the keyword search tool below to find specific information within the annual report.At December 31, 2008, the Partnership owned and operated approximately 3,800 miles of crude oil

pipelines and approximately 2,200 miles of refined product pipelines. In 2008, crude oil and refined product

shipments on these pipelines totaled 24.5 and 17.2 billion barrel miles, respectively, as compared to 23.3 and

18.2 billion barrel miles in 2007 and 21.1 and 17.7 billion barrel miles in 2006. These amounts represent 100

percent of the pipeline shipments of these pipelines.

Product terminalling operations include 43 terminals in the Northeast, Midwest and South Central United

States that receive refined products from pipelines and distribute them to Sunoco and to third parties, who in turn

make deliveries to end-users such as retail outlets. Certain product terminals also provide ethanol blending and

other product additive services. During 2008, 2007 and 2006, throughput at these product terminals totaled 436,

434 and 392 thousand barrels daily, respectively. Terminalling operations also include an LPG terminal near

Detroit, MI, a crude oil terminal complex adjacent to Sunoco’s Philadelphia refinery, ship and barge docks

adjacent to Sunoco’s Eagle Point refinery and a refined products terminal adjacent to Sunoco’s Marcus Hook

refinery. During 2008, 2007 and 2006, throughput at these other terminals totaled 653, 696 and 688 thousand

barrels daily, respectively.

The Partnership’s Nederland, TX terminal provides approximately 17.1 million barrels of storage and

provides terminalling throughput capacity exceeding one million barrels per day. Its Gulf Coast location provides

local, south central and midwestern refiners access to foreign and offshore domestic crude oil. The facility is also

a key link in the distribution system for U.S. government purchases for and sales from certain Strategic

Petroleum Reserve storage facilities. During 2008, 2007 and 2006, throughput at the Nederland terminal totaled

526, 507 and 462 thousand barrels daily, respectively. During 2008, the Partnership continued its construction of

new crude oil storage tanks, four of which were placed into service in 2007 and three in 2008. The Partnership

also continued construction of a crude oil pipeline from the Nederland terminal to Motiva Enterprise LLC’s Port

Arthur, TX refinery and three related storage tanks with a combined capacity of 2.0 million barrels. This project

is expected to be completed in 2009 at a cost of approximately $90 million.

The Partnership’s crude oil pipeline operations in the South Central United States are complemented by

crude oil acquisition and marketing operations. During 2008, 2007 and 2006, approximately 177, 178 and

192 thousand barrels daily, respectively, of crude oil were purchased (including exchanges) from third-party

leases and approximately 402, 400 and 295 thousand barrels daily, respectively, were purchased in bulk or other

exchange transactions. Purchased crude oil is delivered to various trunk pipelines either directly from the

wellhead through gathering pipelines or utilizing the Partnership’s fleet of trucks or third-party trucking

operations.

Coke

SunCoke Energy, Inc., through its affiliates (individually and collectively, “SunCoke Energy”), operates

metallurgical coke plants located in East Chicago, IN (Indiana Harbor), Vansant, VA (Jewell) and Franklin

Furnace, OH (Haverhill) and metallurgical coal mines located in Virginia. SunCoke Energy is also the operator

of a plant in Vitória, Brazil which commenced operations in 2007. During 2007, SunCoke Energy increased its

investment in the project company that developed the Vitória plant by becoming its sole subscriber of preferred

shares for a total equity interest of $41 million.

Aggregate coke production capacity from the plants in the United States approximates 3.02 million tons per

year, while production capacity from the Vitória facility approximates 1.7 million tons per year. The Indiana

Harbor plant can produce approximately 1.22 million tons per year, the Jewell plant can produce approximately

700 thousand tons per year and the Haverhill plant will be capable of producing approximately 1.1 million tons

per year once its expansion is fully operational (see below). In addition, the Indiana Harbor plant produces heat

as a by-product of SunCoke Energy’s proprietary process that is used by a third party to produce electricity. The

Haverhill facility produces steam that is sold to Sunoco’s Chemicals business and electricity from its associated

cogeneration power plant for the regional power market. These facilities use a proprietary low-cost cokemaking

11