HollyFrontier 2014 Annual Report Download - page 21

Download and view the complete annual report

Please find page 21 of the 2014 HollyFrontier annual report below. You can navigate through the pages in the report by either clicking on the pages listed below, or by using the keyword search tool below to find specific information within the annual report.

Table of Content

13

Crude Oil and Feedstock Supplies

The Navajo Refinery is situated near the Permian Basin, an area that has historically, and continues to have, abundant supplies of

crude oil available both for regional users and for export to other areas. We purchase crude oil from independent producers in

southeastern New Mexico and west Texas as well as from major oil companies. The crude oil is gathered through HEP's pipelines,

our tank trucks and through third-party crude oil pipeline systems for delivery to the Navajo Refinery.

We also purchase volumes of isobutane, natural gasoline and other feedstocks to supply the Navajo Refinery from sources in Texas

and the Mid-Continent area that are delivered to our region on a common carrier pipeline owned by Enterprise Products, L.P.

Ultimately all volumes of these products are shipped to the Artesia refining facilities on HEP's intermediate pipelines running

from Lovington to Artesia. From time to time, we purchase gas oil, naphtha and light cycle oil from other refiners for use as

feedstock.

Rocky Mountain Region (Cheyenne and Woods Cross Refineries)

Facilities

The Cheyenne and the Woods Cross Refineries have crude oil processing capacities of 52,000 and 31,000 barrels per stream day,

respectively. The Cheyenne Refinery processes heavy Canadian crudes as well as local sweet crudes such as that produced from

the Bakken shale and similar resources. The Woods Cross Refinery processes regional sweet and black wax crude as well as

Canadian sour crude oils into high-value light products. For 2014, gasoline and diesel fuel (excluding volumes purchased for

resale) represented 56% and 33%, respectively, of our Rocky Mountain sales volumes.

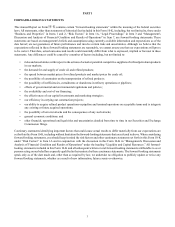

The following table sets forth information about our Rocky Mountain region operations, including non-GAAP performance

measures.

Years Ended December 31,

2014 2013 2012

Rocky Mountain Region (Cheyenne and Woods Cross Refineries)

Crude charge (BPD) (1) 64,820 64,680 73,020

Refinery throughput (BPD) (2) 71,130 70,440 80,860

Refinery production (BPD) (3) 68,140 67,860 78,610

Sales of produced refined products (BPD) 68,520 68,870 77,550

Sales of refined products (BPD) (4) 72,390 72,280 80,980

Refinery utilization (5) 78.1% 77.9% 88.0%

Average per produced barrel (6)

Net sales $ 107.51 $ 112.49 $ 116.44

Cost of products (7) 90.95 94.63 89.29

Refinery gross margin (8) 16.56 17.86 27.15

Refinery operating expenses (9) 10.20 8.65 6.91

Net operating margin (8) $ 6.36 $ 9.21 $ 20.24

Refinery operating expenses per throughput barrel (10) $ 9.83 $ 8.46 $ 6.63

Feedstocks:

Sweet crude oil 44% 43% 47%

Sour crude oil 2% 1% 1%

Heavy sour crude oil 30% 34% 31%

Black wax crude oil 15% 14% 11%

Other feedstocks and blends 9% 8% 10%

Total 100% 100% 100%

Footnote references are provided under our Consolidated Refinery Operating Data table on page 8.

The Cheyenne Refinery facility is located on a 255-acre site and is a fully integrated refinery with crude distillation, vacuum

distillation, coking, FCC, HF alkylation, catalytic reforming, hydrodesulfurization of naphtha and distillates, butane isomerization,

hydrogen production, sulfur recovery and product blending units. The operating units at the Cheyenne Refinery include both newly

constructed units and older units that have been upgraded over the years. Supporting Infrastructure includes approximately 1.9

million barrels of feedstock and product tankage owned by HEP.