Caterpillar 2010 Annual Report Download - page 10

Download and view the complete annual report

Please find page 10 of the 2010 Caterpillar annual report below. You can navigate through the pages in the report by either clicking on the pages listed below, or by using the keyword search tool below to find specific information within the annual report.

10

THINK LIKE YOUR CUSTOMER

For Garney Construction, a large underground and wastewater utility

contractor, quality is essential.

When a machine breaks, Garney crews do not work. Their downtime can cost between $6,000 and $10,000 per day,

depending on the size of the crew. These costs add up fast and profitability can suffer quickly.

Several years ago, Garney faced reliability and availability issues with Cat® excavators that caused this scenario to occur

more than once. As Garney began to question its longtime loyalty to Cat equipment, Caterpillar District Manager Paul Clark

grew concerned and instinctively followed the first rule of customer service: he listened. As Garney’s Steve McCandless

voiced his concerns, Clark realized quickly that other team members needed to hear from McCandless directly. Soon,

McCandless was at Caterpillar’s Aurora plant speaking one-on-one with engineers and production employees.

“Steve pointed out some issues that only someone who operates a machine day

in and day out on different job sites could detect,” explains account manager

Adam Zimmermann. “His comments enabled us to identify improvements quickly

and precisely; nothing can match the value of insights from a customer who uses

our equipment constantly in the field.”

After meeting with Garney, the team went to work,

making standardized changes in both design and

production that would benefit not only Garney, but

other customers as well. Parts that experienced

significant wear in the field, for example, changed

from a bolted to a welded production process.

Today, Garney is a more satisfied customer and

Aurora is a more empowered team.

“Bringing the customer into our everyday work changed our perspective,” adds

Zimmermann. “When you can see firsthand how the quality of a machine improves

jobsite efficiency, it’s powerful and makes us more committed to continuous

improvement than ever.”

Think Quality

We expect a lot from Caterpillar. We expect

world-class products with great reliability,

long life, great parts availability, great field

service and great value.”

Steve McCandless, Senior Vice President

Garney Construction

“

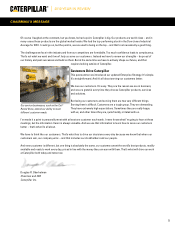

Caterpillar Chairman and CEO Doug

Oberhelman and Garney Senior Vice

President Steve McCandless discuss

expectations for customer focus.

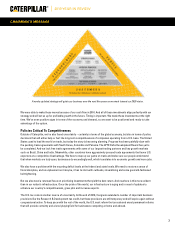

Strategic Thinking

Taking the customer’s view

is a Guiding Principle of

the Caterpillar Production

System (CPS), which, in turn,

is a Caterpillar operating

principle that helps us to

achieve consistency in the

areas of People, Quality,

Velocity and Cost.

2010 YEAR IN REVIEW