Polaris 2010 Annual Report Download - page 8

Download and view the complete annual report

Please find page 8 of the 2010 Polaris annual report below. You can navigate through the pages in the report by either clicking on the pages listed below, or by using the keyword search tool below to find specific information within the annual report.

4

It isn’t enough to have the industry’s most innovative

products. We have to get those products to customers

faster and more cost effectively than anyone else.

A few years ago, we began modifying our manufac-

turing facilities to give us more flexibility, which

allows us to reduce lead times and production

costs — and fundamentally improve how our

powersports vehicles are delivered.

To further improve that capability, we’re concen-

trating our manufacturing in three centers of

excellence — Roseau, Minnesota, Spirit Lake, Iowa,

and a new facility in Monterrey, Mexico (expected

to open in mid-2011), that is closer to growing

demand in the southern United States and Latin

America. While the shift required us to make one

of the most difficult management decisions in

Polaris’ 56-year history — to close and eventually

sell our Osceola, Wisconsin, facility after 19 years

of operation — the move was necessary to make us

more globally competitive.

The key benefit of our manufacturing flexibility

is higher customer satisfaction with less waste,

resulting in higher profits for both us and dealers.

“When Polaris told us we’d be able to order every two

weeks versus every six months, we were skeptical

they could deliver, but they did,” said Matt Kiel, a

15-year Polaris dealer who owns Arizona West

Allsports Inc. in Lake Havasu City. He was referring

to our Max Velocity Program, known as MVP, which

has transformed the retail experience at all our

North American ORV dealerships.

“Now, instead of pulling our best people away from

customers for an extended period of time to try and

guess what to order,” Kiel explained, “I sit down

with a Polaris rep for less than an hour every two

weeks, and we discuss the order based on real sales

and demand.“

The benefits of MVP, he said, include better diversity

of product line for customers, increased sales and

increased value in the Polaris brand, “because we

no longer need to discount the product to unload

excess inventory.” Thanks partially to MVP, North

American dealer inventory for all products combined

is down 20 percent from 2009 levels, and about

50 percent lower than four years ago.

Getting to market faster not only drives retail sales,

it also allows us to test new ideas — like the Polaris

BREEZE™ Neighborhood Electric Vehicle — more cost

effectively than competitors.

“

Matt Kiel, president of Arizona West Allsports Inc. in Lake Havasu City, has seen the benefits of MVP.

I hired two more employees and did

with Polaris this year.

$1 MILLION MORE

”

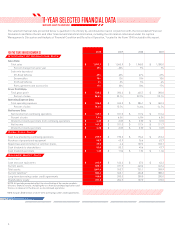

-10%

0807

-5%

09

-24%

-20%

10

FUNDAMENTALLY RESTRUCTURING

THE RETAIL EXPERIENCE

NORTH AMERICAN POLARIS

DEALER INVENTORY LEVELS