Atmos Energy 2014 Annual Report Download - page 6

Download and view the complete annual report

Please find page 6 of the 2014 Atmos Energy annual report below. You can navigate through the pages in the report by either clicking on the pages listed below, or by using the keyword search tool below to find specific information within the annual report.

Pipelines

transport

natural gas to

more than

MILLION

Americans

throughout

the U.S.

Atmos Energy has already removed all cast iron pipelines from its system

in seven states. As part of our comprehensive pipeline infrastructure

program, we will replace all remaining cast iron pipe.

4

“Realizing our goal to be the nation’s safest gas

utility requires us to invest signicant amounts for

rehabilitating, fortifying and replacing our regulated

infrastructure,” Cocklin says.

e company’s scal 2015 capital expenditures are

projected to be between $900 million and $1.0 billion,

with more than 75 percent of these expenditures

earmarked to improve safety and reliability. Capital

spending in each of the scal years 2016 through 2018

should be between $900 million and $1.1 billion.

CALL TO ACTION

ere are many reasons for modernizing aging

pipelines at this time: industry initiatives, federal

laws, safety concerns, regulatory directives, rate-

making mechanisms, environmental goals, energy

eciency, economic development, favorable debt

and equity pricing, and low natural gas prices with

abundant supplies.

Federal oversight of natural gas pipeline safety

began with the Natural Gas Pipeline Safety Act

of 1968. e law required the U.S. Department of

Transportation to establish minimum safety stan-

dards for new pipeline facilities and for the trans-

portation of natural gas.

In 2011, then-DOT Secretary Ray LaHood

announced a national “Call to Action,” directing the

CEOs of pipeline companies to conduct a compre-

hensive review of their pipeline systems.

e secretary acknowledged that safety and

regulatory needs vary in each state. But he called on

state legislators and regulators to enact innovative

rate structures that t their unique circumstances.

LaHood emphasized the need for regulators

to allow timely recovery of these replacement

investments. He said that traditional ratemaking

approaches can impede the imperative to make

improvements.

e 50 states, which oen set more stringent reg-

ulations than federal laws, have stepped up their own

pipeline safety programs. e states have primary

responsibility for regulating natural gas distribution

systems and intrastate pipelines. Federal funding

provides about half the cost of the states’ pipeline in-

spection and enforcement programs, and this support

has helped states focus on pipeline renewal.

SETTING PRIORITIES

e Pipeline and Hazardous Materials Safety

Administration (PHMSA) within the DOT has

identied cast iron and unprotected bare steel pipe-

lines as the pipeline segments to begin replacing rst.

ese materials were once state-of-the-art tech-

nology, enhancing safety and reliability by displacing

earlier piping materials like creosoted wood or clay

pipe. However, pipelines have continually improved

because of better pipe manufacturing, construction

practices, and operation and maintenance.

Cast iron pipe was rst used in the 1830s and

continued being installed until the early 1950s.

Bare steel pipelines were used extensively for gas

mains from the 1900s to the 1960s. Until pipeline

coatings were required by federal mandate in 1970,

some transmission and distribution operators con-

tinued to install bare steel pipelines, particularly in

areas of the country with drier climates.

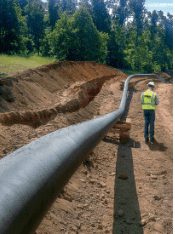

Atmos Energy has already removed all cast iron

pipelines from its system in seven states. As part of

our comprehensive pipeline infrastructure program,

we will replace all remaining cast iron pipe and

will rehabilitate or replace the remaining bare steel

pipelines in our system.

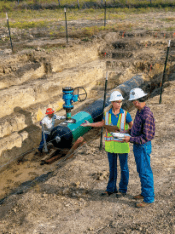

Cast iron distribution mains top the list of pipelines scheduled for

replacement across the country. Although some cast iron lines have

operated safely for more than 100 years, aging iron pipe can turn

brittle and crack if the ground shifts or the pipe is damaged by

excavation. Behind houses in Highland Park, Texas, Juan Gomez

(top right), a senior field construction coordinator, oversees

replacing a cast iron main with high-density polyethylene pipe.

ATMOS ENERGY: INVESTING FOR SAFETY

177