Valero 2013 Annual Report Download - page 11

Download and view the complete annual report

Please find page 11 of the 2013 Valero annual report below. You can navigate through the pages in the report by either clicking on the pages listed below, or by using the keyword search tool below to find specific information within the annual report.

18 19

2013 SUMMARY ANNUAL REPORT 2013 SUMMARY ANNUAL REPORT

After receiving the industry’s most prestigious

safety award in 2011, the Valero Houston Refinery

might have been forgiven a performance letdown

since. But that hasn’t happened. Far from it.

For two out of the past four years, the refinery has

been the most reliable in the Valero system, with

no unplanned major-unit outages in 2013, placing

it in the top quarter of the industry in mechanical

availability, and recording the longest time

between needed

pump repairs among

Valero refineries.

And then there

was this: It set

a plant record

for profitability

in 2013. The

correlation between

performance and

profits is not lost

on Valero’s top

management.

“When refineries

are available to run,”

says Lane Riggs,

Valero Executive Vice

President-Refining

Operations and

Engineering, “the

opportunity is there to set records.”

Improving refining operations is at the forefront of

Valero’s strategy to enhance returns and increase

long-term shareholder value. The company’s

pursuit of excellence in operations is driving

its goal to achieve “first-quartile,” or industry

top-quarter, performance across key refining

benchmarks.

Industry surveys reflect significant improvement

across Valero’s refining system during the past

six years, including its highest-ever mechanical

availability – the percentage of time a plant’s

equipment is available for operation. Other

improvements have come in maintenance, energy

efficiency and operating cost. Valero expects

further improvements as its reliability programs

continue to mature.

“This pattern of continuing improvement in

reliability reflects our employees’ commitment to

making our reliability programs effective, and to

improving our turnaround execution,” Riggs said. In

addition to Houston’s

performance,

Valero’s Jean Gaulin

refinery in Quebec

achieved 100

percent mechanical

availability, outside

of turnarounds, in

2013.

Importantly, a reliable

operation drives

improved safety

and environmental

performance.

Safety is Valero’s

No. 1 priority.

The company’s

frequency of “Tier

1” process safety

events – as defined

by American Petroleum Institute practice – has

steadily decreased, with event rates dropping 63

percent since 2008. The performance reflects a

sharp focus on materials and inspection, rotating

equipment reliability, electrical reliability, and

automation and controls effectiveness.

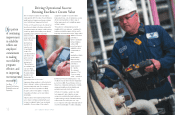

At Houston, for example, operators use high-

tech equipment to detect vibration on large

compressors, and IntelaTrac hand-held devices

to gather and log a variety of information during

routine rounds. The refinery also uses “rope-

access” inspectors who rappel down large units to

check the metal integrity of columns and piping.

Driving Operational Success:

Pursuing Excellence Creates Value

is pattern

of continuing

improvement

in reliability

reflects our

employees’

commitment

to making

our reliability

programs

effective, and

to improving

our turnaround

execution.

Lane Riggs

Executive Vice President-

Refining Operations and

Engineering