Electrolux 2003 Annual Report Download - page 9

Download and view the complete annual report

Please find page 9 of the 2003 Electrolux annual report below. You can navigate through the pages in the report by either clicking on the pages listed below, or by using the keyword search tool below to find specific information within the annual report.

Electrolux Annual Report 2003 7

More efficient purchasing

In 2003 the Group spent about SEK 90

billion on purchases of materials and

services. Direct materials, including

components, accounted for about two

thirds of total purchases. In recent

years we have succeeded in steadily

reducing our annual purchasing costs.

In the coming years we expect to

obtain even greater savings, through

continued internal coordination and

consolidation, increased purchases

from Eastern Europe and Asia, and

standardization of components and

products.

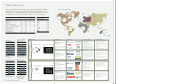

Investments in Eastern Europe, Mexico and Asia

Increased

New plant in New plant in capacity in New plant in New plant in

Hungary Russia Poland Mexico Thailand

Product Refrigerators/ Washing Dryers Refrigerators Washing

freezers machines machines

Annual capacity 560,000 150,000 From 200,000 1,600,000 200,000

(Phase 1) to 800,000

Investment SEK 600m SEK 80m SEK 270m SEK 1,500m SEK 80m

Start of production 2005 2004 2006 2005 2003

Increased purchases

from low-cost countries

2003 2006

The goal is to increase the share of

purchases from low-cost countries

from about 20% today to about

40% in 2006.

40%

20%

Examples of regional production costs

Estimated landed cost for two different appliances

Relocating production facilities

The trend towards greater globalization of

products and markets creates opportunities

for shifting production to low-cost countries.

Building on our global structure, we’re expand-

ing our production base in Mexico, Eastern

Europe and Asia. The costs for relocation could

reach SEK 1–2 billion annually in the next few

years, which is in line with the Group’s previous

restructuring costs.

However, a major share of restructuring

costs in recent years was related to units that

are no longer part of the Group. The actions

that we are now taking are related directly to

our core businesses and should therefore make

a more positive contribution to profitability.

Western

Europe China Eastern

Europe

Washing machine

for EU market

Region of production

US China Mexico

Chest-freezer

for US market

Logistics

Direct Labor

& Overhead

Materials &

Components

Region of production

In the examples above, production in Mexico and Eastern

Europe is competitive with China and Korea.

Investment decisions in 2003 included two new plants in Eastern Europe, i.e. one in

Hungary for refrigerators and one in Russia for washing machines, as well as one

plant for washing machines in Thailand. We also decided to increase capacity at the

plant for dryers in Poland. In 2004, we decided to invest in a new plant for refrigerators

in Mexico.

The diagrams show the current total cost of

a chest-freezer sold in the US and a washing

machine sold in the EU. The cost of produc-

ing the chest-freezer in Mexico, including

purchases of materials and components from

low-cost countries, is fully competitive with

costs for a corresponding product produced

in Asia. Wages are higher in Mexico, but this

is offset by higher transport costs from Asia

to the US market. Cost relations are similar

for a washing machine produced in Eastern

Europe.

Cost-efficiency