Atmos Energy 2014 Annual Report Download - page 9

Download and view the complete annual report

Please find page 9 of the 2014 Atmos Energy annual report below. You can navigate through the pages in the report by either clicking on the pages listed below, or by using the keyword search tool below to find specific information within the annual report.

7

Today,

natural gas

utilities spend

more than

$19

BILLION

annually to

help enhance

the safety

of natural

gas delivery

systems.

We plan to replace between 450 and 500 miles of distribution

pipelines,

70 to 90 miles of transmission pipelines and some 25,000

customer service lines during fiscal 2015.

ATMOS ENERGY: INVESTING FOR SAFETY

Replacing aging pipelines in communities involves a constant watch

for safety and close coordination with local authorities, emergency

officials and affected customers. In Gretna, Louisiana, a suburb

of New Orleans, Atmos Energy is modernizing its distribution

pipelines in older sections of the city by replacing bare steel pipe

with high-density polyethylene pipe.

FISCAL 2015 PROJECTED PIPELINE REPLACEMENTS

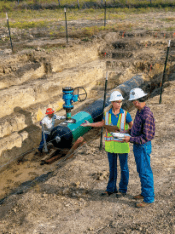

ENSURING PIPELINE INTEGRITY

Although much of the nation’s current natural gas

infrastructure was installed before 1970, the eect

of age is not the only factor—or the most signicant

one—for assessing a pipeline’s tness for service.

Along with the material that a pipe is made of,

operators must consider construction practices and

other factors that could aect pipeline integrity. Soil

conditions, erosion, drought, rainfall, wind, tree

roots, maintenance records, whether a line has a

protective coating, the proximity to populated loca-

tions and data collected from a variety of inspection

methods—all have a bearing on a pipeline’s integrity.

In 2004, federal regulations began requiring

operators of natural gas transmission pipelines to

conduct integrity management programs for their

pipeline systems. A similar regulation took eect for

natural gas distribution pipelines in 2011.

Integrity management programs require a

comprehensive examination of pipeline infra-

structure. Federal and state rules require pipeline

operators to assess threats to their system, apply risk

analysis to grade the signicance of those threats

and take both preventative and mitigative actions

to protect the public from incidents. Our integrity

management plans are shared with the safety regula-

tors in each of the states we serve.

Integrity management programs can involve

running precise instruments through the pipeline,

called pigging, to search for corrosion or cracks,

excavating around the line to directly inspect the

pipe’s condition or performing a hydrostatic pres-

sure test of a line segment to ensure it can withstand

much higher-than-normal pressure.

A LONG-TERM UNDERTAKING

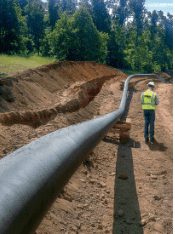

Based on risk analysis and integrity management

data, Atmos Energy currently expects to replace

its existing cast iron and most of its bare steel and

vintage plastic pipelines during the next two decades.

We also plan to continue replacing between 75 miles

and 100 miles a year of older coated steel pipelines.

During scal 2014, Atmos Energy replaced about

375 miles of distribution pipelines, some 95 miles

of transmission pipelines and approximately 23,000

service lines to customers’ premises.

We plan to replace between 450 and 500 miles of

distribution pipelines, 70 to 90 miles of transmission

pipelines and some 25,000 customer service lines

during scal 2015. Replacements of cast iron pipe in

the Mid-Tex Division should increase by one-third,

from about 60 miles in scal 2014 to about 80 miles

in scal 2015.

DISTRIBUTION PIPELINES: 450– 500 MILES

CAST IRON

COATED STEEL

VINTAGE PLASTIC

BARE STEEL

SERVICE LINES

TRANSMISSION PIPELINES: 70–90 MILES

25,000 SERVICES

0 50 100 150 200 MILES