Vistaprint 2010 Annual Report Download - page 16

Download and view the complete annual report

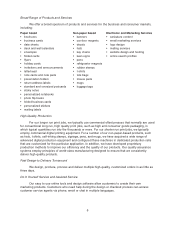

Please find page 16 of the 2010 Vistaprint annual report below. You can navigate through the pages in the report by either clicking on the pages listed below, or by using the keyword search tool below to find specific information within the annual report.cost efficient for the type of product ordered. Printed products ordered in larger quantities, such as

business cards, postcards, letterhead and the like, are typically produced using a single pass on state

of the art automated, high-volume, offset, professional quality printing presses. Products produced in

smaller quantities or using special materials, such as holiday cards, apparel, signage, invitations,

return address labels, and magnets, are typically produced on digital equipment. In most cases,

individual orders from multiple customers are aggregated to create larger jobs, allowing multiple

orders to be simultaneously produced.

Our proprietary Viper software and sophisticated automation solutions combined with software

from our suppliers allow us to integrate and automate the manufacturing process. This process

includes:

• the pre-press process, during which digital files are transferred directly from our computer

servers to the manufacturing system at the appropriate production facility;

• automatic plate loading systems that eliminate all manual steps of offset printing other than

a quick ‘toaster like’ insertion and removal of plates;

• automatic ink key setting whereby ink fountain keys, which control color application, are set

automatically from an analysis of the pixelized data used to image plates; and

• automated color management, which adjusts digital images prior to printing, assuring that

colors match when processed across different printing presses and substrates.

Once printed, individual paper product orders are separated using computerized cutting

systems, assembled, packaged, addressed using Vistaprint’s proprietary Viper software, and shipped

to the customer. Viper processes then communicate electronically with shipping carriers, assuring

smooth tracking and information flow to the customer until final confirmation of delivery.

Requiring as little as 60 seconds of pre-press, printing and cutting labor for a typical order of

250 business cards, versus an hour or more for traditional printers, this process enables us to print

many high quality customized orders using a fraction of the labor of typical traditional printers. Our

quality control systems are designed around the principles of world class manufacturing to ensure that

we consistently deliver premium, high quality products.

Sales and Marketing

We have developed expertise in direct marketing to target new customers across various

channels and to drive more sessions on our websites, as well as to retain existing customers.

To acquire new customers, we employ sophisticated direct marketing technologies and

management practices using the Internet, e-mail, and traditional direct marketing mailings. Through

channels such as our own permission-based outbound emails and direct URL type-in, we are able to

secure orders at relatively low cost. In addition, many of the products that we offer our customers

contain the Vistaprint logo and reference our website. Our products, by their nature, are purchased by

our customers for the purpose of being further distributed to business or personal contacts. As such,

the appearance of our brand on the products yields broad and ongoing distribution and visibility of our

brand and presents the opportunity for beneficial viral and word-of-mouth advertising.

We have developed tools and techniques for measuring the result of each provider of direct

marketing services and of each marketing message or product or service offer. In addition, our

customer split-run testing technology allows us to divide prospective or returning customers visiting

our websites into sub-groups that are presented with different product and service selections, prices

and/or marketing messages. This allows us to test or introduce new products and services on a

12