Vistaprint 2010 Annual Report Download - page 14

Download and view the complete annual report

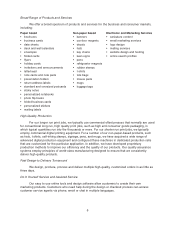

Please find page 14 of the 2010 Vistaprint annual report below. You can navigate through the pages in the report by either clicking on the pages listed below, or by using the keyword search tool below to find specific information within the annual report.production facilities by using complex algorithms to aggregate pending individual print jobs having

similar printing parameters and combine the compatible orders into a single production run or set of

homogenous production runs. The technology calculates the optimal allocation of print orders that will

result in the lowest production cost but still ensure on-time delivery. In our fiscal year ended June 30,

2010 we averaged approximately 52,000 orders per day and orders often contain multiple customized

items, which can result in more than 100,000 individual stored items awaiting production. Our

aggregation software regularly scans these pending jobs and analyzes a variety of production

characteristics, including quantity, type and format of raw material, color versus black and white,

single or double-sided print, delivery date, shipping location, type of production system being used

and type of product. For printed products, the VistaBridge software then automatically aggregates

orders with similar production characteristics from multiple customers into a single document image

that is transferred to either a digital press or to an automated plating system that produces offset

printing plates. For example, in the case of business cards being printed on large offset presses, up to

143 separate customer orders can be simultaneously printed as a single aggregated print file.

Viper is our workflow and production management software for tracking and managing our

worldwide production facilities on a networked basis. Viper monitors and manages bar-code driven

production batch and order management, pick and pack operations, and addressing and shipping of

orders.

Marketing Technologies

We use our marketing technologies to test changes to our websites and new product offers in

order to enhance our offerings and customer value proposition. In addition, we automatically generate

and display additional products incorporating the customer’s initial design, facilitating the cross-sale of

related products and services.

Split Run Testing technology assigns our website visitors to test and control groups. Depending

on the test group to which a visitor is assigned, he or she can be shown slightly different versions of

our website. This technology permits us to evaluate changes to our websites on a relatively small but

still statistically significant test group prior to general release. We then use analytics software to

correlate the changes on the site with the visitor’s browsing and purchasing behavior and to compare

our profitability for a given pair of test and control groups. Our testing engine allows us to run

hundreds of these tests simultaneously on our websites, reducing the time to take an idea from

concept to full deployment and allowing us to quickly identify and roll-out the most promising and

profitable ideas and promotions to maximize our customer value proposition.

VistaMatch Software automatically generates and displays one or more additional customized

product designs based upon a customer’s existing design. Design elements and customer information

are automatically transferred to the additional design so that customers do not spend additional time

searching for other products or templates or re-entering data. For example, a customer purchasing

business cards can automatically be shown matching return address labels, magnets, calendars,

T-Shirts, pens, websites and similar products. Each of these automatically generated product offers

can be quickly and simply added to the customer’s order..

Automated Cross-Sell and Up-Sell technology permits us to show a customer, while the

customer is in the process of purchasing a product, marketing offers for one or more additional or

related products. We use this technology to dynamically determine the most effective products to offer

to customers based on a number of variables including how the customer reached the website, the

customer’s purchase history, the contents of the customer’s shopping basket and the various pages

within the website that the customer has visited.

Localization/Language Map is our content management system that permits all of our localized

websites, and the changes to those websites, to be managed by the same software engine. Text and

10