Plantronics 2011 Annual Report Download - page 15

Download and view the complete annual report

Please find page 15 of the 2011 Plantronics annual report below. You can navigate through the pages in the report by either clicking on the pages listed below, or by using the keyword search tool below to find specific information within the annual report.

Computer OEMs include both manufacturers of computer hardware (including PCs and specialized components and accessories

for PCs) and software. Most computer OEMs do not manufacture headsets but look for manufacturers such as Plantronics to

supply headsets that can be used with their products. We supply certain headsets to computer OEMs particularly for use in UC

systems.

We also make direct sales as a General Services Administration (“GSA”) contractor to certain government agencies, including the

National Aeronautics and Space Administration ("NASA") and the Federal Aviation Administration ("FAA"). In addition, certain

distributors are authorized resellers under a GSA schedule price list and sell our products to government customers pursuant to

that agreement. These sales did not comprise a significant portion of our net revenues in fiscal 2011.

Our products may also be purchased directly from our website at www.plantronics.com.

We continue to evaluate our logistics processes and implement new strategies to further reduce our transportation costs and improve

lead-times to customers. Currently, we have distribution centers located in the following locations:

• Tijuana, Mexico, which provides logistics services for products destined for customers in the U.S., Canada, Asia Pacific,

and Latin America regions;

• Prague, Czech Republic, which provides logistics services for products shipped to customers in our Europe, Middle East

and Africa regions;

• Suzhou, China, which provides logistics services for products which are shipped within Mainland China;

• Melbourne, Australia, which provides logistics services for products which are shipped to the retail channel in Australia

and New Zealand;

• Sao Paulo, Brazil, which provides logistics services for products which are shipped to customers within Brazil; and

• Tokyo, Japan, which provides logistics services for products which are shipped to customers within Japan.

With respect to the above locations, we use third party warehouses in the Czech Republic, Australia, Brazil, and Japan. We operate

all other warehouse facilities.

BACKLOG

Our backlog of unfilled orders was $29.6 million at March 31, 2011 compared to $31.4 million at March 31, 2010. We include

all purchase orders scheduled for delivery over the next 12 months in backlog. We have a “book and ship” business model whereby

we fulfill the majority of our orders within 48 hours of our receipt of the order. Our backlog is occasionally subject to cancellation

or rescheduling by the customer on short notice with little or no penalty. Because of our “book and ship” model, as well as the

uncertainty of order cancellations or rescheduling, we do not believe our backlog as of any particular date is indicative of actual

sales for any future period and, therefore, should not be used as a measure of future revenue.

MANUFACTURING AND SOURCES OF MATERIALS

Manufacturing operations consist primarily of assembly and testing which is performed in our manufacturing facilities in Tijuana,

Mexico, and we maintain a small assembly operation in California primarily for custom products. In March 2009, we entered

into an agreement with GoerTek, Inc., an existing third party contract manufacturer, to outsource the manufacturing of our Bluetooth

products in China which resulted in the discontinuance of manufacturing of our Bluetooth products at the Suzhou, China facility

in fiscal 2010. In addition, we outsource the manufacturing of a limited number of our other products to third parties, typically

in China and other countries in Asia. See further discussion on our business risks associated with our manufacturers under the

risk titled “We depend on original design manufacturers and contract manufacturers who may not have adequate capacity to fulfill

our needs or may not meet our quality and delivery objectives which could have an adverse effect on our business” within Item

1A Risk Factors of this 10-K.

We purchase the components for our products, including proprietary semi-custom integrated circuits, amplifier boards and other

electrical components, primarily from suppliers in Asia, Mexico, the U.S., and Europe. The majority of our components and sub-

assemblies used in our manufacturing operations are obtained, or are reasonably available, from dual-source suppliers, although

we do have a certain number of sole-source suppliers. The earthquake, tsunami and nuclear issues arising in Japan in March 2011

have not materially interfered with our supply chain; however, we cannot predict what impact, if any, these events may have in

the future.

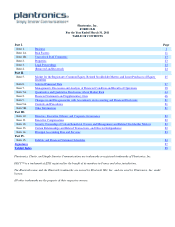

Table of Contents

6