PBF Energy 2013 Annual Report Download - page 14

Download and view the complete annual report

Please find page 14 of the 2013 PBF Energy annual report below. You can navigate through the pages in the report by either clicking on the pages listed below, or by using the keyword search tool below to find specific information within the annual report.

7

capability up to 210,000 bpd by the end of 2014, subject to the delivery of coiled and insulated railcars, the

development of crude rail loading infrastructure in Canada and the use of unit trains.

We have entered into agreements to lease or purchase a total of 5,900 railcars, including 4,600 coiled and

insulated rails cars, which are capable of transporting Canadian heavy crude oils, and 1,300 general purpose cars,

which we intend to use to transport lighter crude oils. In addition to the construction of our rail unloading facilities

at Delaware City and the execution of our railcar procurement strategy, we also created dedicated crude-by-rail

acquisition and rail logistics teams. These teams, staffed by PBF employees in our corporate headquarters, at the

Delaware City refinery and in our field offices in Calgary, Alberta and Oklahoma City, Oklahoma, are responsible

for crude procurement, logistics via rail and monitoring crude-by-rail offloading.

Overview. The Delaware City refinery is located on a 5,000-acre site, with access to waterborne cargoes

and an extensive distribution network of pipelines, barges and tankers, truck and rail. Delaware City is a fully

integrated operation that receives crude via rail at the crude unloading facility, or ship or barge at its docks located

on the Delaware River. The crude and other feedstocks are transported, via pipes, to an extensive tank farm where

they are stored until processing. In addition, there is a 17-bay, 50,000 bpd capacity truck loading rack located

adjacent to the refinery and a 23-mile interstate pipeline that are used to distribute clean products.

The Delaware City refinery has a throughput capacity of 190,000 bpd and a Nelson Complexity Index of

11.3. As a result of its configuration and process units, Delaware City has the capability of processing a slate of

heavy crudes with a high concentration of high sulfur crudes and is one of the largest and most complex refineries

on the East Coast. The Delaware City refinery is one of two heavy crude coking refineries, the other being Paulsboro,

on the East Coast of the United States with coking capacity equal to approximately 25% of crude capacity.

The Delaware City refinery processes a variety of medium to heavy, sour crude oils. The refinery has large

conversion capacity with its 82,000 bpd FCC unit, 47,000 bpd FCU and 18,000 bpd hydrocracking unit with

vacuum distillation. Hydrogen is provided via the refinery’s steam methane reformer and continuous catalytic

reformer.

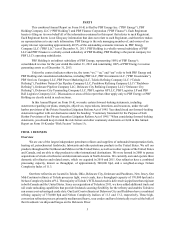

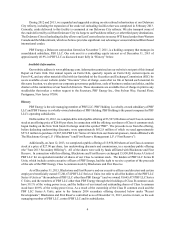

Delaware City Process Flow Diagram

Naphtha

Kerosene

Di l

Naptha

Tetra feed Benzene

CCR

Tetra

Extraction

ULSD

BB

Diesel

Reformate

Crude

Distillation

Hydrotreaters

Coker

Middle

Distillate

Crude

Heating Oil

B-B

Isobutane

ATB

Gas oil Butane

Gasoline

ISOM

Poly

Alky

FCC

(Sales)

Gas oil

Light

Cycle Oil

P-P

Slurry

Gas oil Gasoline

Naphtha to HDS

Vacuum

Distillation

CNHTU

SHU

(Sales)

Heavy

Cycle Oil

Gas oil

VTB

Naphtha to HDS

Naphtha

Fluid Coker

Diesel

SHU

Hydrocracker

Gas Oil

Coke