Nucor 2011 Annual Report Download - page 6

Download and view the complete annual report

Please find page 6 of the 2011 Nucor annual report below. You can navigate through the pages in the report by either clicking on the pages listed below, or by using the keyword search tool below to find specific information within the annual report.

5

Highlighting a few key investments, construction began on Phase I of an ironmaking facility on 4,000 acres in St. James Parish,

Louisiana, and is proceeding on schedule. We continue to expect start-up in mid-2013. This first phase, with an annual capacity of

2.5 million tons per year, will bring us closer to our long-term objective to control between six and seven million tons of high-quality

scrap substitutes, supplementing the expansion at our ironmaking facility in Trinidad from 1.8 million metric tons to 2.0 million

metric tons.

The new facility will use a proven technology to convert iron ore pellets, utilizing efficient, low-cost natural gas as the reductant,

into high-quality direct reduced iron (DRI). DRI is used by our steel mills, along with recycled scrap, in producing numerous

high-quality steel products such as sheet, plate and special bar quality (SBQ) steel. Fracking, a process that fractures rock to

release natural gas, promises to make natural gas even more plentiful and affordable. While we realize the fracking process has

generated some recent controversy, we are confident that careful extraction practices will provide a valuable, plentiful, low-cost

source of natural gas for generations to come. In fact, it is a major “game changer” for our country and U.S.-based manufacturing.

We commissioned a heat treating facility at our plate mill in Hertford County, North Carolina during 2011. The heat treat line has an

estimated annual capacity of 125,000 tons and has the ability to produce heat treated plate from 3

/

16 of an inch through 2 inches thick.

Our new Kingman, Arizona, wire rod and rebar mill and SBQ mill in Memphis, Tennessee, achieved profitability by the first quarter

of 2011. We also installed a new quality assurance line at our SBQ mill in Norfolk, Nebraska, while our Darlington, South Carolina,

mill implemented new casting practices that enabled it to expand its presence in higher quality SBQ applications. Our SBQ mills

have been and will continue to be a source of growth as we grow our core product range and expand market penetration.

Our joint venture in Italy, Duferdofin Nucor, revamped the finishing rolling mill of its steel beam plant in Pallanzeno, Verbania, in the

northwestern region of Piedmont. The project also included a state-of-the-art rolling mill control system.

DJJ continued its growth by completing four acquisitions since mid-2010. The DJJ team has also continued the development and

refinement of new technologies to extract significantly higher ferrous and non-ferrous metal yields from shredded scrap.

These highlighted projects are just a sample of

the many projects our teams are undertaking

to grow our long-term earnings power in every

part of the company. From 2008 through 2011,

we invested more than $2 billion in projects

to continually improve our existing operations

at every level. Supported by our prudent

investments, our product groups continue to

expand further up the value chain, while retaining leadership positions in our current markets.

While 2011 saw significant new regulations imposed on Nucor, our environmental performance continued to improve. We are

pushing forward with innovative measures to ensure our continued full compliance with both existing and new regulations. In

January 2011, Nucor Louisiana received the first major source permit issued in the United States under the new greenhouse

gas rules imposed by the EPA, demonstrating our ability to permit projects that others view as extremely difficult or impossible.

Our environmental staff continues to find economic opportunities to improve compliance and decrease costs while helping our

operations manage the impact of new regulations on our company.

Working Together

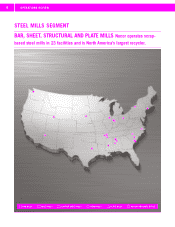

Our improved results in 2011 benefited greatly from our position as North America’s most diversified steelmaker. Product diversification is

a critical building block in the business model that drives Nucor’s industry-leading, through-the-cycle return on capital performance.

Our product diversity is evidenced by the fact that our largest product categories — sheet steel, steel bars, structural steel, steel

plate, scrap and steel products — each represent more than 10% of our total sales tons.

THESE HIGHLIGHTED PROJECTS ARE JUST A SAMPLE OF THE MANY

PROJECTS OUR TEAMS ARE UNDERTAKING TO GROW OUR LONG-TERM

EARNINGS POWER IN EVERY PART OF THE COMPANY. FROM 2008 THROUGH

2011, WE INVESTED MORE THAN $2 BILLION IN PROJECTS TO CONTINUALLY

IMPROVE OUR EXISTING OPERATIONS AT EVERY LEVEL.