Valero 2010 Annual Report Download - page 5

Download and view the complete annual report

Please find page 5 of the 2010 Valero annual report below. You can navigate through the pages in the report by either clicking on the pages listed below, or by using the keyword search tool below to find specific information within the annual report.

3TO OUR SHAREHOLDERS

LETTER TO SHAREHOLDERS

One year ago, we made a pledge to focus on

strategic items that would restore protability and

help us become a world-class rening industry

competitor. Valero has made great progress by

staying focused, working wisely and rising above

political and economic challenges.

During 2010, the world economy recovered faster

and stronger than expected, contributing to a surge

in global demand for rened products. At the same

time, the U.S. economy has been slowly recovering.

Rening margins and crude oil discounts, measured

against foreign sweet crude oil, improved

substantially over the past year. Our capital projects

and recent transactions have added value and a

competitive edge to our rening portfolio. On top

of all of this, the commitment of our people has

made a real dierence in countless ways – from

a return to protability through execution and

cost-control to improved lives in our communities

through our tireless volunteers.

In 2010, we focused on new workplace safety

programs, cut costs, and relentlessly looked for ways

to be more ecient, more competitive and more

protable. The results were excellent: improved

safety and reliability, divestiture of underperforming

assets, progress on major capital projects, signicant

cost reductions, the acquisition of three more

world-class ethanol plants and our best operational

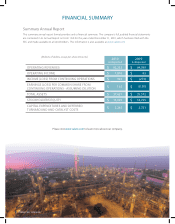

performance in ve years. For 2010, Valero reported

income from continuing operations of $923 million,

or $1.62 per share.

As we look to an even better 2011, here are

additional highlights from 2010:

SAFETY OUR HIGHEST PRIORITY

The safety of our people always comes rst and is

the most important eort we make every day. In

2010 we began tracking a new industry metric on

loss of containment, called API process safety events,

and have increased our eorts to eliminate losses

of containment across all of our facilities. We also

adopted “Life-Saving Rules,” a program that identies

the most common causes of serious injuries and

raises individual accountability to follow basic

accident-prevention rules. Our rening system’s

average total recordable-incident rate (TRIR) was

the second-lowest in company history, and our

contractors recorded their lowest-ever TRIR. Our

employees and contractors know that safety is

everyone’s priority, and that by working together,

our safety performance will continue to improve.

IMPROVED RELIABILITY WITH CONTINUED FOCUS

ON OPERATIONAL EXCELLENCE INITIATIVES

In 2010, we made signicant progress in key

reliability measures. Our Commitment to Excellence

Management System (CTEMS) is now in its third

year, delivering a standardized framework for

safety, operational excellence and reliability. We

also are improving reliability through aggressive

preventive maintenance programs, standardized

incident tracking tools, retrospective positive

material identication, and electrical and mechanical

inspections. Since 2007, the cost of high-impact

outages in our renery system has dropped more

than 70 percent.

IMPROVED OPTIMIZATION AND PRODUCT YIELDS

High-value rened products and liquid volume

yield are increasingly important. Through catalyst

optimization, attention to detail and better