Sunoco 2009 Annual Report Download - page 19

Download and view the complete annual report

Please find page 19 of the 2009 Sunoco annual report below. You can navigate through the pages in the report by either clicking on the pages listed below, or by using the keyword search tool below to find specific information within the annual report.

Jewell plant can produce approximately 700 thousand tons per year, the Indiana Harbor plant can produce

approximately 1.22 million tons per year, the Haverhill plant can produce approximately 1.1 million tons per

year and the Granite City plant can produce approximately 650 thousand tons per year. In addition, the Indiana

Harbor plant produces heat as a by-product of SunCoke Energy’s proprietary process that is used by a third party

to produce electricity; the Haverhill facility produces steam that is sold to Sunoco’s Chemicals business and

electricity from its associated cogeneration power plant for sale in the regional power market; and the Granite

City facility produces steam that is sold to a third party. These coke plants use a technology with several

proprietary features.

Sunoco received a total of $415 million in exchange for interests in its Indiana Harbor cokemaking

operations in two separate transactions in 1998 and 2002. Sunoco did not recognize any gain as of the dates of

these transactions because the third-party investors were entitled to a preferential return on their respective

investments. The returns of the investors were equal to 98 percent of the cash flows and tax benefits from such

cokemaking operations during the preferential return period, which continued until the fourth quarter of 2007 (at

which time both investors had recovered their investment and achieved a cumulative annual after-tax return of

approximately 10 percent). Those investors are now entitled to a noncontrolling interest amounting to 34 percent

of the partnership’s net income, which declines to 10 percent by 2038.

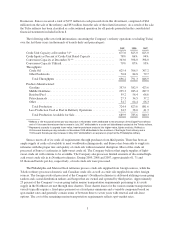

The following table sets forth information concerning cokemaking and coal mining operations:

2009 2008 2007

Production (Thousands of Tons):

Coke:

United States ............................................. 2,868 2,626 2,469

Brazil ................................................... 1,266 1,581 1,091

Metallurgical Coal ........................................... 1,134 1,179 1,220

Proven and Probable Metallurgical Coal Reserves

at December 31 (Millions of Tons) .............................. 99 100 101

In 2009, 86 percent of SunCoke Energy’s metallurgical coal production was converted into coke at the

Jewell plant, 12 percent was converted into coke at the Indiana Harbor, Haverhill and Granite City plants and 2

percent was sold in spot market transactions.

Most of the metallurgical coal used to produce coke at the Indiana Harbor, Haverhill and Granite City

cokemaking operations is purchased from third parties. Sunoco believes there is an ample supply of metallurgical

coal available, and it has been able to supply these facilities without any significant disruption in coke

production.

Substantially all coke sales from the Indiana Harbor and Jewell plants and 50 percent of the production from

the Haverhill plant are made pursuant to long-term contracts with affiliates of ArcelorMittal. The balance of coke

produced at the Haverhill plant is sold to AK Steel and the coke produced at the Granite City plant is sold to US

Steel, each under long-term contracts. In addition, the technology and operating fees, as well as preferred

dividends pertaining to the Brazilian cokemaking operation are payable to SunCoke Energy under long-term

contracts with a project company in which a Brazilian subsidiary of ArcelorMittal is the major shareholder.

There has been no indication that ArcelorMittal, AK Steel or US Steel will not perform under those contracts.

However, in the event of nonperformance, SunCoke Energy’s results of operations and cash flows would be

adversely affected.

Production from the Indiana Harbor plant is sold and delivered to ArcelorMittal’s Indiana Harbor Works

steel plant, which is adjacent to the Indiana Harbor coke plant. The coke purchase agreement requires SunCoke

Energy to provide ArcelorMittal with 1.22 million tons of coke annually on a take-or-pay basis through 2013.

Where available, any additional production is sold either to ArcelorMittal or to other steel producers. Indiana

11