Atmos Energy 2015 Annual Report Download - page 6

Download and view the complete annual report

Please find page 6 of the 2015 Atmos Energy annual report below. You can navigate through the pages in the report by either clicking on the pages listed below, or by using the keyword search tool below to find specific information within the annual report.

89

We train our employees to evaluate every situa-

tion carefully, to rely on engineering controls, to

always protect customers and the public first and

to safeguard local first responders from taking

undue risks.

Hazard prevention is standard procedure at

Atmos Energy and is rooted in our safety policies,

personal protective equipment practices, Material

Safety Data Sheet procedures, hazardous sub-

stance training as well as basic and advanced

skills courses.

Trevor Brewer (center), a senior service technician

in our Kentucky/Mid-States Division at Columbia, Tennessee,

is one of the company’s Safety Champions. They share

their knowledge about proper operating procedures with

fellow employees and encourage their peers to discuss ways

to improve safety on the job and at home.

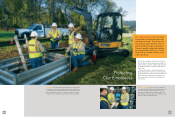

Shoring is an extension of the personal protective equipment that

our employees must use. All excavations below a specific depth must be

protected with proper shoring equipment or the ditch must be tiered to

proper standards to avoid a cave-in. Advanced training is required for

employees who are authorized to supervise these types of excavations.

Protecting

Our Employees

Our service employees are much better

trained today, using improved techniques,

technologies and tools. They rely on care-

fully designed safety procedures when re-

sponding to all natural gas service requests.

They are especially vigilant when handling

any emergency call, whether it’s a suspect-

ed gas leak or a situation involving a haz-

ardous gas release.