Atmos Energy 2015 Annual Report Download - page 11

Download and view the complete annual report

Please find page 11 of the 2015 Atmos Energy annual report below. You can navigate through the pages in the report by either clicking on the pages listed below, or by using the keyword search tool below to find specific information within the annual report.

18 19

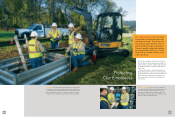

Accurate and up-to-date records are essential

to document all the work we do on our pipelines, whether installing

a new facility, repairing it, reconfiguring it or replacing it. We have

launched a major information technology project to deliver state-of-

the-art recordkeeping for our construction and replacement projects.

Above, Daniel Waguespack, Lousiana Division compliance manager,

notes changes to be made to an existing installation.

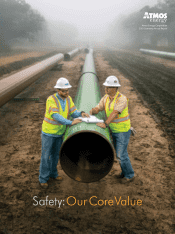

Our goal at Atmos Energy is to be

the safest natural gas provider in the United

States. We take pride in all our achievements

and improvements. Yet, we remain focused

on being incident-free every day. Safety is our

core value.

To improve our performance, we participate

in the AGA’s peer-evaluation program of safety

practices. Beginning with 10 pilot companies, the

program now has 50 participating utilities. Its key

topics are: a culture of safety, worker procedures

and risk management.

We also participate in quarterly outside audits

of company safety processes. Conducted by our

primary insurance provider, these Loss Control

Reviews are rotated among our operating divisions

to examine and assess safety procedures and to

share best practices.

We are especially proud that Atmos Energy em-

ployees have taken leading roles on safety commit-

tees at both the AGA and the Southern Gas Asso-

ciation. And, in key safety measures, Atmos Energy

has a robust process for continuous improvement.

It encourages enhancements to safety procedures

and processes as we adopt new technologies and

modernize our pipeline infrastructure.

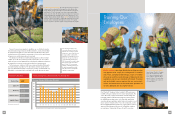

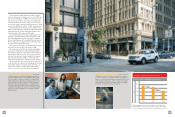

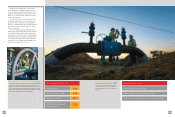

Key Safety Results: 2010 –2015 Staying Focused on Safety

Invest in employees and infrastructure

Explore innovative technologies to enhance safety

Conduct rigorous, multi-year planning for continuous improvement

Active leaks down 31%

Enterprise damage rate down 19 %

Employee injuries down 35%

Approximate miles of bare steel,

1,000

cast iron and early-generation

plastic pipe replaced