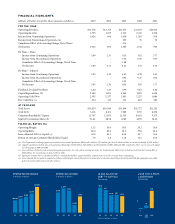

Union Pacific 2005 Annual Report Download - page 4

Download and view the complete annual report

Please find page 4 of the 2005 Union Pacific annual report below. You can navigate through the pages in the report by either clicking on the pages listed below, or by using the keyword search tool below to find specific information within the annual report.SAFETY FIRST

Union Pacic’s approach to safety is one of zero tolerance.

Although the rail industry is already one of the safest in

America, we are working daily to improve. In 2005, our

number of derailments improved 8 percent and the

associated costs decreased 12 percent. We also enhanced

grade crossing safety through the closure of 400 rail

crossings and the installation of 750 locomotive video

cameras. Cameras provide valuable evidence for accident

investigations

. In 2006, we will continue our focus on

employee safety education and training, public awareness

and derailment prevention.

OPERATING INITIATIVES

Strong business demand and signicant attrition in our

aging workforce required additional resources to meet the

needs of our customers. Last year, we continued eorts

begun in 2004 to bolster the Railroad’s critical assets -

employees, locomotives and freight cars. We hired and

trained nearly 2,100 conductors and 1,700 engineers and

added 317 new fuel-ecient, emissions-compliant

locomotives and 4,200 freight cars. We also increased our

network capacity through targeted capital spending in

some of our fastest growing corridors. Our Intermodal

capacity increased with the opening of new facilities in

Dallas and Salt Lake City, we installed 69 miles of double

track on our Sunset Corridor and 14 miles of triple track

to the SPRB Joint Line.

We began implementing our Unied Plan in April,

instituting changes to our transportation plan. e Unied

Plan is one of several network initiatives started in 2005 to

redesign and simplify our operations. e goal is to increase

velocity and improve customer service by reducing the

workload on the network. Two areas targeted by the Unied

Plan are main line train stops and terminal switching.

At the beginning of the year, only a third of UP’s regularly

scheduled trains moved from origin to destination without

stopping. e average manifest car was switched three

times before arriving at its destination. rough the Unied

Plan, our rate of train stops declined 16 percent and our car

switching rate decreased 12 percent. is work links directly

to improved terminal dwell time and reduced rail car

inventory we experienced in 2005. We have more hard work

ahead of us to increase eciency, but customers are starting

to recognize our eorts and are working with us to make

operational changes.

We are also improving terminal eciency through a newly

developed technology tool called our Customer Inventory

Management System (CIMS). We use CIMS to proactively

manage terminal inventory and increase asset utilization

as well as help customers improve processing eciency.

e overall goal is to generate more terminal throughput

with existing capacity. e initial CIMS pilot location was

Phoenix. We subsequently rolled it out to major terminals in

Las Vegas, Los Angeles, San Antonio and Houston, covering

40 percent of daily industry switching. In 2006, we plan to

implement CIMS in additional terminals, including Salt

Lake City, Roseville, Portland, Seattle, Fort Worth, Kansas

City and Little Rock.

Velocity was relatively unchanged versus 2004, largely due

to the many weather issues we faced. Increasing network

velocity is a key objective for 2006, and a continued emphasis

on Unied Plan compliance is vital to achieving that goal.

In conjunction with the Unied Plan, we are increasing

capacity by employing industrial engineering strategies that

require little or no capital investment. For example, we

initiated projects to:

• improve system velocity by reducing terminal dwell time,

• increase locomotive availability by decreasing locomotive

service time,

• conserve fuel by reducing locomotive fuel consumption

through technology and training, and

• facilitate volume growth by de-bottlenecking constrained

terminals, intermodal yards and key rail corridors.

Additionally, teams in Phoenix, Houston, Kansas City and

Los Angeles have studied trac ows, operating practices

and processes to increase throughput in these capacity-

constrained areas.

ANOTHER YEAR OF RECORD FUEL PRICES

Following a more than 40 percent increase in diesel fuel

prices in 2004, we experienced another huge increase in

2005. Our average diesel fuel price in the rst quarter was

$1.45 per gallon, but it increased to $2.08 per gallon by the

fourth quarter. Two factors drove the increase: crude oil

prices and rening spreads. Aer starting the year at about

$40 per barrel, the price of crude oil topped out over $70 per

barrel in September. In addition, rening spreads nearly

tripled following the fall hurricanes.

Although somewhat mitigated by our fuel surcharge

programs, rising fuel prices decreased our 2005 operating

income. Our goal is 100 percent recovery of higher fuel

costs to eliminate the earnings impact. Longer-term,

high fuel prices create a competitive advantage for us, as

rail transportation is three times more fuel ecient than

trucking. We also increased our emphasis on fuel

conservation through engineer training and improved

locomotive technology. In 2005, our consumption rate

improved by 2 percent, saving 35 million gallons of fuel.

2