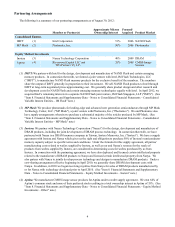

Crucial 2012 Annual Report Download - page 6

Download and view the complete annual report

Please find page 6 of the 2012 Crucial annual report below. You can navigate through the pages in the report by either clicking on the pages listed below, or by using the keyword search tool below to find specific information within the annual report.5

On August 30, 2012, we had a 50% interest in Transform Solar Pty Limited ("Transform"), a joint venture with Origin

Energy Limited ("Origin"). Transform developed and manufactured photovoltaic solar panels. As a result of the ongoing

challenging global environment in the solar industry and unfavorable worldwide supply and demand conditions, on May 25,

2012, the Board of Directors of Transform approved a liquidation plan. As of August 30, 2012, the operations of Transform

were substantially discontinued. (See "Item 8. Financial Statements and Supplementary Data – Notes to Consolidated Financial

Statements – Equity Method Investments – Transform" note.)

Manufacturing

Our manufacturing facilities are located in the United States, China, Israel, Italy, Malaysia, Puerto Rico and Singapore.

Our Inotera joint venture also has a wafer fabrication facility in Taiwan. In 2011, we sold our wafer fabrication facility in Japan

to Tower Semiconductor Ltd. ("Tower") and entered into a supply agreement for Tower to manufacture products for us in the

facility through approximately May 2014. Our manufacturing facilities generally operate 24 hours per day, 7 days per week.

Semiconductor manufacturing is extremely capital intensive, requiring large investments in sophisticated facilities and

equipment. A significant portion of our semiconductor equipment is replaced every three to five years with increasingly

advanced equipment. NAND Flash, DRAM and NOR Flash products share common manufacturing processes, enabling us to

leverage our product and process technologies and manufacturing infrastructure across these product lines.

Our process for manufacturing semiconductor products is complex, involving a number of precise steps, including wafer

fabrication, assembly and test. Efficient production of semiconductor products requires utilization of advanced semiconductor

manufacturing techniques and effective deployment of these techniques across multiple facilities. The primary determinants of

manufacturing cost are process line-width, number of mask layers, number of fabrication steps and number of good die

produced on each wafer. Other factors that contribute to manufacturing costs are wafer size, cost and sophistication of

manufacturing equipment, equipment utilization, process complexity, cost of raw materials, labor productivity, package type

and cleanliness of the manufacturing environment. We continuously enhance our production processes, reducing die sizes and

transitioning to higher density products. In 2012, most of our NAND Flash memory products were manufactured on our 25nm

line-width process technology. We expect that for the second half of 2013 a majority of our NAND Flash production will be

manufactured on our 20nm line-width process technology. In 2012, the majority of our DRAM production was manufactured

on 42nm line-width process technology. We expect that for 2013 the majority of our DRAM production will be manufactured

on 30nm line-width process technology. Our NOR Flash memory products in 2012 were manufactured on our 65nm and 45nm

line-width process technologies. In 2012, we manufactured all of our high-volume NAND Flash and DRAM products on

300mm wafers. We manufactured NOR Flash, some specialty DRAM and CMOS image sensor products on 200mm wafers in

2012.

Wafer fabrication occurs in a highly controlled, clean environment to minimize dust and other yield- and quality-limiting

contaminants. Despite stringent manufacturing controls, equipment errors, minute impurities in materials, defects in

photomasks, circuit design marginalities or defects and dust particles can lead to wafers being scrapped and individual circuits

being nonfunctional. Success of our manufacturing operations depends largely on minimizing defects to maximize yield of

high-quality circuits. In this regard, we employ rigorous quality controls throughout the manufacturing, screening and testing

processes. We are able to recover certain devices by testing and grading them to their highest level of functionality.

After fabrication, most silicon wafers are separated into individual die. We sell semiconductor products in both packaged

and unpackaged (i.e. "bare die") forms. For packaged products, functional die are sorted, connected to external leads and

encapsulated in plastic packages. We assemble products in a variety of packages, including TSOP (thin small outline package),

TQFP (thin quad flat package) and FBGA (fine pitch ball grid array). Bare die products address customer requirements for

smaller form factors and higher memory densities and provide superior flexibility for use in packaging technologies such as

system-in-a-package ("SIPs") and MCPs, which reduce the board area required.

We test our products at various stages in the manufacturing process, perform high temperature burn-in on finished products

and conduct numerous quality control inspections throughout the entire production flow. In addition, we use our proprietary

AMBYX™ line of intelligent test and burn-in systems to perform simultaneous circuit tests of semiconductor memory die

during the burn-in process, capturing quality and reliability data and reducing testing time and cost.

We assemble a significant portion of our memory products into memory modules. Memory modules consist of an array of

memory components attached to printed circuit boards that insert directly into computer systems or other electronic devices.

We also contract with independent foundries and assembly and testing organizations to manufacture NAND Flash media

products such as memory cards and USB devices.