Nikon 2009 Annual Report Download - page 11

Download and view the complete annual report

Please find page 11 of the 2009 Nikon annual report below. You can navigate through the pages in the report by either clicking on the pages listed below, or by using the keyword search tool below to find specific information within the annual report.

Review of the Year Ended March 2009

In the IC steppers and scanners field, Nikon took steps to

expand sales of cutting-edge equipment such as the NSR-

S610C ArF immersion scanner (the world’s first scanner

capable of mass production of semiconductors at 45 nm

applications and beyond), and marketed EUV lithography

equipment (extreme ultraviolet system for research and

development) that enables further device shrinkage.

In the LCD steppers and scanners field, Nikon worked

to expand sales of the existing FX-65S model for litho-

graphic exposure of 6th generation glass plates, as well

as the FX-903N model, which is ideally suited for the

manufacture of the small to medium-sized high-precision

liquid crystal displays used in cell phones and automotive

electronic devices. In addition, we initiated shipments of

FX-101S lithography equipment, which is compatible with

10th generation glass plates.

We also continued our concerted efforts throughout the

Precision Equipment Company to boost cost-competitive-

ness by shortening manufacturing periods, as well as

adopting simplified designs and common platforms.

NSR-S620 ArF Immersion Scanner to Be Introduced

in the Year Ending March 2010

Despite the difficult business environment for IC steppers

and scanners, for the year ending March 2010 Nikon is

focusing on double patterning,*1 one of the most promis-

ing next-generation lithography techniques. Specifically,

we are developing an ArF immersion scanner for double

patterning that will allow for 32 nm device production.

For successful development, two issues must be resolved.

The first is improvement in alignment accuracy. Since

double patterning involves the overlaying of two layers to

create the pattern, alignment requires extreme precision.

Currently, the alignment accuracy requirement is around

7 nm, but double patterning will require a reduction to

half or even one-third of that figure.

The second issue is enhancing throughput (the number

of wafers exposed in a given period). Since double pat-

terning consists of two exposures, the throughput must be

doubled to maintain the current level of productivity in

the customer’s manufacturing process.

The NSR-S620 ArF immersion scanner for mass pro-

duction with double patterning that Nikon will introduce

utilizes new concepts which will provide the necessary

precision and throughput. This system will be extremely

competitive not only in terms of precision alignment but

also in offering an exceptional throughput level, an aspect

in which our rival has been considered superior. We plan

to begin shipments in the third quarter of the year end-

ing March 2010 (October to December 2009). We have

adopted a new design concept for the NSR-S620 in which

the overall system is created from 13 individual modules,

allowing for a considerably shorter period from shipment

to operation at the customer’s site.

Currently Nikon is constructing a new building at the

Kumagaya Plant with a highly efficient clean room that

will be used to produce the NSR-S620 and enhance its

competitiveness. With the focus of effort on the NSR-

S620, Nikon seeks to quickly gain a leading share of the

market for high-end IC steppers and scanners.

Note:

1. Double patterning is a lithography technique in which a single, dense circuit

pattern is split into two coarser patterns that can be exposed separately. The two

patterns can then be overlaid on the wafer, providing a final, dense circuit pattern.

MARKET ENVIRONMENT AND BUSINESS TRENDS

Business conditions for the semiconductor-related industry will likely remain difficult, with device manufacturers showing

continued caution regarding capital expenditures. The LCD panel market is also expected to lack transparency, despite some

signs of rising operation rates among panel manufacturers.

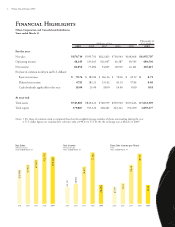

219,915

290,814

291,913

200920082007

Net Sales

(Millions of yen)

Years ended March 31

Operating Income

(Millions of yen)

Years ended March 31

8,041

43,348

49,321

200920082007

Nikon Annual Report 2009 9