Nikon 2005 Annual Report Download - page 11

Download and view the complete annual report

Please find page 11 of the 2005 Nikon annual report below. You can navigate through the pages in the report by either clicking on the pages listed below, or by using the keyword search tool below to find specific information within the annual report.

High throughput, improved alignment accuracy and the

incorporation of an ultra-high N.A. projection lens enable the

mass production of next-generation 110nm devices with this

lens scanning KrF excimer stepper.

NSR-S208D

LCD exposure system business performing

well as panel sizes increase

The LCD exposure system business posted excel-

lent results in the year ended March 2005. Nikon

has developed an original multi-lens scanning

system for use in LCD exposure systems that is

ideally suited to larger substrates. This applica-

tion of parallel multi-lens units promises to result

in greater benefi ts for LCD manufacturers as

panel sizes continue to increase. In June 2005,

Nikon began shipment of the latest LCD exposure

systems for 7th and 8th generation production

processes (FX-71S).

Reductions achieved in stepper lead times

and costs

A major factor in the turnaround in profi tability

of Nikon’s precision equipment operations has

been a steep reduction in scanner production

lead times. For leading-edge IC scanners, it now

takes about six months from lens fabrication to

fi nal installation, which is roughly half the previ-

ous fi gure. Simplifi ed design has played a part

in this achievement, covering all processes from

development and design to technical and manu-

facturing steps. Nikon teams have also worked

with external contractors to reduce lead times

and achieve demanding performance targets.

The benefi ts of simplifi ed design are only just

becoming apparent, and Nikon expects the new

processes to generate further productivity gains

going forward. Nikon has also thoroughly revised

the sequence within manufacturing to eliminate

any waste created by repeated processes. On

the product side, Nikon has sought to improve

the quality of the fi nished form in production

to eliminate any interference between modules,

thereby reducing assembly time. The reductions

in lead times achieved to date have also gener-

ated substantial cost reductions.

FX-81S

This large-plate exposure system supports eighth-

generation plate sizes for LCDs, with improved

throughput and a multi-lens projection optical

system for greater productivity.

NSR-SF140

Providing superior cost performance, high resolution and

throughput, this i-line scan fi eld stepper is optimized for mix-

and-match solutions. 11, 3 87

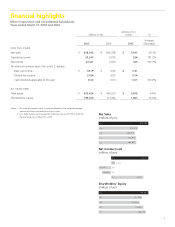

(20,806)

(24,595)

05

04

03

Operating Income (Loss)

(millions of yen)

Net Sales*

(millions of yen)

214,326

158,054

133,102

05

04

03

CY 01 02 03 04 05 06 07 08 09 10 11 12 13 14 15 16

Technology Node hp130 hp90 hp65 hp45 hp32 hp22

DRAM Half Pitch130 115 10 0 90 807065 57 50 45 40 35 32 2825 22

MPU Gate in resist 90 65 53 45 40 35 32 2825 22 20 1817 15 13

post-etch65 45 37 32 2825 22 20 1816 14 13 11 10 9

Nikon Lithography Roadmap

*The above fi gures include intersegment sales.

Critical layer

exposure

method

KrF

248nm

ArF EUV

13nm

193nm

dry immersion

(water)

EPL 100keV

ITRS 2004

9