National Oilwell Varco 2011 Annual Report Download - page 10

Download and view the complete annual report

Please find page 10 of the 2011 National Oilwell Varco annual report below. You can navigate through the pages in the report by either clicking on the pages listed below, or by using the keyword search tool below to find specific information within the annual report.

Index to Financial Statements

Turret Mooring Systems. The Company acquired Advanced Production and Loading PLC (APL), in December 2010. APL, based in Norway, designs and manufactures

turret mooring systems and other products for FPSOs and other offshore vessels and terminals. A turret mooring system consists of a geostatic part attached to the seabed and

a rotating part integrated in the hull of the FPSO, which are connected and allow the ship to weathervane (rotate) around the turret.

Facilities. The Companys Rig Technology segment conducts manufacturing operations at major facilities in Houston, Galena Park, Sugar Land, Conroe, Cedar Park,

Anderson, Fort Worth and Pampa, Texas; Duncan, Oklahoma; Orange, California; Edmonton, Canada; Aberdeen, Scotland; Kristiansand, Stavanger and Arendal, Norway;

Etten-Leur and Groot-Ammers, the Netherlands; Carquefou, France; Singapore; Lanzhou and Shanghai, China; Dubai, UAE; and Ulsan, South Korea. For a more detailed

listing of significant facilities see Item 2. Properties. The Rig Technology segment maintains sales and service offices in most major oilfield markets, either directly or

through agents.

Customers and Competition. Rig Technology sells directly to drilling contractors, other rig fabricators, well servicing companies, pressure pumping companies, national oil

companies, major and independent oil and gas companies, supply stores, and pipe-running service providers. Demand for its products is strongly dependent upon capital

spending plans by oil and gas companies and drilling contractors, and the level of oil and gas well drilling activity.

The products of the Rig Technology segment are sold in highly competitive markets and its sales and earnings can be affected by competitive actions such as price changes,

new product development, or improved availability and delivery. The segments primary competitors are Access Oil Tools; Aker Solutions AS; American Block; Bomco;

Canrig (a division of Nabors Industries); Cavins Oil Tools; Cameron; DenCon Oil Tools; Forum Oilfield Technologies; General Electric; Hitec Drilling Products; Hong Hua;

Huisman; Global Energy Services; M&I Electric; Tesco Corporation; Stewart & Stevenson, Inc.; Huntings, Ltd.; Vanoil; Parveen Industries; Soilmec; TTS Sense; Omron;

Bentec; Blohm; Voss; Liebher; Seatrax; McGregor; Rolls Royce and Weatherford International, Inc. Management believes that the principal competitive factors affecting its

Rig Technology segment are performance, quality, reputation, customer service, availability of products, spare parts, and consumables, breadth of product line and price.

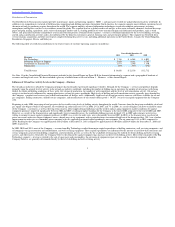

Petroleum Services & Supplies

The Company provides a broad range of support equipment, spare parts, consumables and services through the Petroleum Services & Supplies segment. Petroleum Services &

Supplies segment sells directly and provides a variety of tubular services, composite tubing, and coiled tubing to oil and gas producers, national oil companies, drilling

contractors, well servicing companies, and tubular processors, manufacturers and distributors. These include inspection and reclamation services for drill pipe, casing,

production tubing, sucker rods and line pipe at drilling and workover rig locations, at yards owned by its customers, at steel mills and processing facilities that manufacture

tubular goods, and at facilities which it owns. The Company also provides internal coating of tubular goods at several coating plants worldwide and through licensees in

certain locations. Additionally, the Company designs, manufactures and sells high pressure fiberglass and composite tubulars for use in corrosive applications and coiled

tubing for use in well servicing applications and connections for large diameter conductor pipe.

The Companys customers rely on tubular inspection services to avoid failure of tubing, casing, flowlines, pipelines and drill pipe. Such tubular failures are expensive and in

some cases catastrophic. The Companys customers rely on internal coatings of tubular goods to prolong the useful lives of tubulars and to increase the volumetric throughput

of in-service tubular goods. The Companys customers sometimes use fiberglass or composite tubulars in lieu of conventional steel tubulars, due to the corrosion-resistant

properties of fiberglass and other composite materials. Tubular inspection and coating services are used most frequently in operations in high-temperature, deep, corrosive oil

and gas environments. In selecting a provider of tubular inspection and tubular coating services, oil and gas operators consider such factors as reputation, experience,

technology of products offered, reliability and price.

The Petroleum Services & Supplies segment also provides products and services that are used in the course of drilling oil and gas wells. The NOV Downhole business sells

and rents bits, drilling motors and specialized downhole tools that are incorporated into the drill stem during drilling operations, and are also used during fishing, well

intervention, re-entry, and well completion operations. The Wellsite Services business provides products and services such as drilling fluids, highly-engineered solids control

equipment, waste handling and treatment, completion fluids, power generation equipment, and other ancillary well site equipment and services. Wellsite Services is also

engaged in barium sulfate (barite) mining operations in the State of Nevada. Barite is an inert powder material used as the primary weighting agent in drilling fluids.

Additionally, efficient separation of drill cuttings enables the re-use of often costly drilling fluids. The Pumps & Expendables business provides centrifugal, reciprocating, and

progressing cavity pumps and pump expendables (Pumps & Expendables) into the global oil and gas and industrial markets.

Solids Control and Waste Management. The Company is engaged in the provision of highly-engineered equipment, products and services which separate and manage drill

cuttings produced by the drilling process (Solids Control). Drill cuttings are usually contaminated with petroleum or drilling fluids, and must be disposed of in an

environmentally sound manner.

9