Atmos Energy 2011 Annual Report Download - page 7

Download and view the complete annual report

Please find page 7 of the 2011 Atmos Energy annual report below. You can navigate through the pages in the report by either clicking on the pages listed below, or by using the keyword search tool below to find specific information within the annual report.

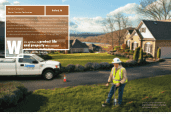

Corrosion Control Technician James

Sparks of the Kentucky/Mid-States

Division, who is a recognized expert

on cathodic protection, inspects our

natural gas system in Kentucky.

James Sparks

Corrosion Control Technician Madisonville, KY

Age is only one factor that affects the integrity of a buried gas pipeline. Even more telling is

how the pipe has been inspected and maintained. “There are thousands of miles of pipeline

in the Atmos Energy network, and we are checking them constantly,” says Corrosion Control

Technician James Sparks. “We put better corrosion-detection processes in place almost 20

years before the government required it. Because of our cathodic protection procedures, 50

years from now when we dig out a piece of pipe, it should look very similar to the way it did

the day we put it in the ground.”

Ihave been at this more than 40

years—long enough to see that

our safety measures

really work.

ATMOS ENERGY 2011 SUMMARY ANNUAL REPORT 98 ATMOS ENERGY 2011 SUMMARY ANNUAL REPORT