AMD 1999 Annual Report Download - page 13

Download and view the complete annual report

Please find page 13 of the 1999 AMD annual report below. You can navigate through the pages in the report by either clicking on the pages listed below, or by using the keyword search tool below to find specific information within the annual report.Manufacturing Facilities

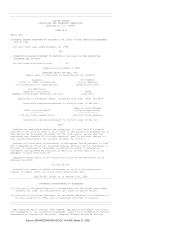

Our current IC manufacturing facilities are described in the chart set forth

below:

Production

Technology Approximate

Wafer Size (in Clean Room

Facility Location (Diameter in Inches) Microns) (Square Footage)

----------------- -------------------- ----------- ----------------

Austin, Texas

Fab 25................... 8 0.18 120,000

Fab 14/15(1)............. 6 0.5 42,000

Aizu-Wakamatsu, Japan

FASL(2).................. 8 0.35 70,000

FASL II(2)............... 8 0.25 & 0.35 91,000

Sunnyvale, California

SDC...................... 8 0.18 & 0.25 42,500

--------

(1) We consolidated our Fab 14 and Fab 15 operations in 1999.

(2) We own 49.992 percent of FASL. Fujitsu owns 50.008 percent of FASL.

AMD Saxony Manufacturing GmbH, an indirect wholly owned German subsidiary of

AMD, has constructed and is installing equipment in Dresden Fab 30, a 900,000-

square-foot submicron integrated circuit manufacturing and design facility

located in Dresden, in the State of Saxony, Germany. The building construction

of FASL II, a second Flash manufacturing facility, was completed, equipment

was installed and production was initiated in 1999. We also have foundry

arrangements for the production of our products by third parties.

Our current assembly and test facilities are described in the chart set

forth below:

Approximate

Assembly & Test

Facility Location Square Footage Activity

----------------- --------------- ---------------

Penang, Malaysia............................. 377,000 Assembly & Test

Bangkok, Thailand............................ 78,000 Assembly & Test

Singapore.................................... 162,000 Test

Suzhou, China................................ 30,250 Assembly & Test

We began operations in our new assembly and test facility in Suzhou during

the first quarter of 1999. Foreign manufacturing and construction of foreign

facilities entails political and economic risks, including political

instability, expropriation, currency controls and fluctuations, changes in

freight and interest rates, and loss or modification of exemptions for taxes

and tariffs. For example, if we were unable to assemble and test our products

abroad, or if air transportation between the United States and our overseas

facilities were disrupted, there could be a material adverse effect on our

business.

Certain Material Agreements. Set forth below are descriptions of certain

material contractual relationships we have relating to FASL, Dresden Fab 30

and Motorola.

FASL. In 1993, we formed FASL, a joint venture with Fujitsu, for the

development and manufacture of Flash memory devices. FASL operates two

advanced IC manufacturing facilities in Aizu-Wakamatsu, Japan, for the

production of Flash memory devices. FASL began volume production in the first

quarter of 1995, and utilizes eight-inch wafer processing technologies capable

of producing products with geometrics of .35 micron or smaller. FASL II began

volume production in 1999, and utilizes eight-inch wafer processing

technologies.

We expect FASL II, including equipment, to cost approximately $1 billion

(denominated in yen) when fully equipped. Capital expenditures for FASL II

construction to date have been funded by cash generated from FASL operations

and local borrowings by FASL. To the extent that FASL is unable to secure the

necessary funds for FASL II, we may be required to contribute cash or

guarantee third-party loans in proportion to our 49.992 percent interest in

FASL. As of December 26, 1999, we had loan guarantees of $2 million

(denominated in yen)

9

Source: ADVANCED MICRO DEVIC, 10-K405, March 21, 2000