Toro 2011 Annual Report Download - page 11

Download and view the complete annual report

Please find page 11 of the 2011 Toro annual report below. You can navigate through the pages in the report by either clicking on the pages listed below, or by using the keyword search tool below to find specific information within the annual report.PVC tubing, in order to enable growers to complete their Toro enables operators to quickly change snow-throwing direction. Our

micro-irrigation system. innovative pivoting scraper is designed to keep the rotor in con-

stant contact with the pavement. Our two-stage snow throwers are

Residential – We market our residential products to homeowners generally designed for relatively large areas of deep, heavy snow

through a variety of distribution channels, including outdoor power and use four-cycle engines. Our two-stage snow throwers include

equipment dealers, hardware retailers, home centers, mass retail- a line of innovative models featuring the Power Max姞 auger sys-

ers, and over the Internet. These products are sold mainly in North tem for enhanced performance and the Quick Stick姞 chute control

America, Europe, and Australia, with the exception of snow technology.

removal products that are sold primarily in North America and

Europe. We also license our trade name to other manufacturers Financial Information about Foreign Operations

and retailers on certain riding and home solutions products as a and Business Segments

means of expanding our brand presence. We currently manufacture our products in the United States, Mex-

Walk Power Mower Products. We manufacture and market ico, Australia, the United Kingdom, and Italy for sale throughout

numerous walk power mower models under our Toro and the world and, in late fiscal 2011, we completed the construction of

Lawn-Boy brand names, as well as the Pope brand in Australia our new manufacturing facility in Romania. We maintain sales

and the Hayter brand in the United Kingdom. Models differ as to offices in the United States, Belgium, the United Kingdom, France,

cutting width, type of starter mechanism, method of grass clipping Australia, Singapore, Japan, China, Italy, Korea, and Germany.

discharge, deck type, operational controls, and power sources, and New product development is pursued primarily in the United

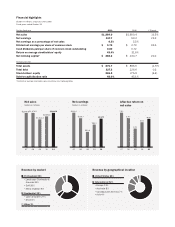

are either self-propelled or push mowers. We also offer a line of States. Our net sales outside the United States were 32.3 percent,

rear-roller walk power mowers, a design that provides a striped 31.8 percent, and 32.0 percent of total consolidated net sales for

finish, for the United Kingdom market. fiscal 2011, 2010, and 2009, respectively.

A portion of our cash flow is derived from sales and purchases

Riding Products. We manufacture and market riding products denominated in foreign currencies. To reduce the uncertainty of

under the Toro brand name worldwide and under the Hayter brand foreign currency exchange rate movements on these sales and

name in the United Kingdom. Riding products primarily consist of purchase commitments, we enter into foreign currency exchange

zero-turn radius mowers that save homeowners time by using contracts for select transactions. For additional information regard-

superior maneuverability to cut around obstacles more quickly and ing our foreign currency exchange contracts, see Part II, Item 7A,

easily than tractor technology. Lawn and garden tractor models are ‘‘Quantitative and Qualitative Disclosures about Market Risk’’ of

sold worldwide. In addition, our rear engine and direct-collect riding this report. For additional financial information regarding our foreign

mowers are manufactured and sold in the European market. Many operations and each of our three reportable business segments,

models are available with a variety of engines, decks, transmis- see Note 12 of the Notes to Consolidated Financial Statements, in

sions, and accessories. In fiscal 2011, we introduced the TimeCut- the section entitled ‘‘Segment Data,’’ included in Part II, Item 8,

ter姞 SS zero-turn radius mower with our innovative Smart Speed姠‘‘Financial Statements and Supplementary Data’’ of this report.

control system, which is designed to allow the operator to choose

different ground speed ranges with the flip of a lever and without Engineering and Research

changing the blade or engine speed. We also introduced the We are committed to an ongoing engineering program dedicated to

TITAN MX mower, which is designed to bridge the gap between developing innovative new products and improvements in the qual-

commercial-grade zero-turn radius mowers and residential models ity and performance of existing products. However, a focus on

and is loaded with user-friendly features. innovation also carries certain risks that new technology could be

Home Solutions Products. We design and market home solu- slow to be accepted or not accepted by the marketplace. We

tions products under the Toro and Pope brand names, including attempt to mitigate these risks through our focus on and commit-

electric and battery operated flexible line grass trimmers, electric ment to understanding our customers’ needs and requirements.

blower-vacuums, electric blowers, and electric snow throwers. In We invest time upfront with customers, using ‘‘Voice of the Cus-

Australia, we also design and market underground and hose-end tomer’’ tools, to help us develop innovative products that we

retail irrigation products under the Pope brand name. expect to meet or exceed customer expectations. We use Design

for Manufacturing and Assembly (‘‘DFM/A’’) tools to ensure early

Gas Snow Removal Products. We manufacture and market a manufacturing involvement in new product designs to reduce pro-

range of gas-powered single-stage and two-stage snow thrower duction costs. DFM/A focuses on reducing the number of parts

models. Single-stage snow throwers are walk behind units with required to assemble new products, as well as designing products

lightweight two- and four-cycle gasoline engines. Most single-stage to move more efficiently through the manufacturing process. We

snow thrower models include Power Curve姞 snow thrower technol-

ogy and some feature our Quick Shoot姠 control system that

5