Kenwood 2004 Annual Report Download - page 13

Download and view the complete annual report

Please find page 13 of the 2004 Kenwood annual report below. You can navigate through the pages in the report by either clicking on the pages listed below, or by using the keyword search tool below to find specific information within the annual report.

Profitability (30% Cost Reduction)

Cash Flow (50% Inventory Reduction)

Defect Rate Reduce to 1/4

Unified Community KENWOOD Group

KENWOOD Quarter QCD Revolution

Reduction Cost and Administrative Expenses Reduction 1/4

Manufacturing-to-Sales Lead Time Reduce to 1/4

Quality

Cost

Delivery

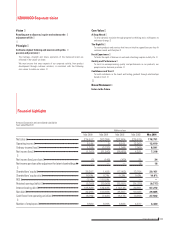

Transition of inventory and receivables

Inventory Trade notes and accounts receivable

(Billions of yen)

60

0

20

40

2003/32002/3 2004/3

Transition of cash flow

Cash flows from operating activities Cash flows from investing activities

(Billions of yen)

30

-30

-15

0

15

2003/32002/3 2004/3

Cash flows from financial activities

57.6

43.3

34.6

32.3 30.9

24.6

-6.8

-5.9

-12.8

-8.0

10.4

-7.7

15.2 1.0

27.5

Transceiver system provided to West Maclaren

Mercedes Team, as an official supplier

Production innovations-Best practice reflected on all

production sites at home and abroad

In March 2003, the Company launched a production innovation project to further

improve profits and cash flows through "Kenwood Quarter QCD (quality, cost and

delivery) Revolution"-the supply chain management (SCM) overhaul targeting

production, marketing and technology. The themes of the project were "revival of

domestic plants to outdo Asian peers" and "reinforcing overseas plants'

competitiveness."

The best practical example for the project was the return of the production of

portable MD players for the Japanese market from the Malaysian plant to the

factory in Yamagata (Japan), where manufacture resumed in September 2003.

The move resulted in a reduction in costs, a substantial cut in the lead time from

manufacturing to marketing, and a decrease in the percentage of defective

products, which helped turn a profit in the home electronics business in the

second half of the year and contributed to improving cash flows.

In a similar move, the Company shifted the production of "Theater Navi," a high

potential audio-visual hard disc navigation system, from the Nagano plant to the

Yamagata factory, where manufacture of the product started in January 2004,

while positioning the Nagano plant as the main production center of OEM car

electronics products. This production innovations were adopted in the car

electronics business. Through these moves, the Company established a system

to propagate best practice methods at all manufacturing bases both in Japan and

overseas.

As a result, inventories decreased approximately 7.7 billion yen from the

previous year. Cash flows from operating activities increased about 17.1 billion

yen, marking a significant improvement, due to cuts in inventories, a sharp rise in

net income and a reduction in accounts receivable due to restructuring of

marketing functions. In addition, indirect fixed costs and direct processing costs

declined, wastage costs decreased thanks to improved product quality, and

procurement costs went down owing to innovative procurement activities.

Reduction in these costs translated into an increase in earnings for every

business division.

Development of new product lines

The Company strove to develop new product lines leveraging its core

competencies, "audio" and "radio communication" technologies, aiming to

establish the "Mobile & Home Multimedia Systems" business.

In the car electronics business, the Company enjoyed strong sales of DVD

theater systems that use proprietary audio and multimedia technologies, as well

as "Theater Navi," an audio-visual hard disc navigation system that integrates

DVD theater and automotive navigation systems for the domestic market. The

Company strengthened its multimedia equipment lines, through development of

tuners for digital satellite broadcasting (provided by Sirius Satellite Radio, Inc. of

the United States) and the first civilian use of tuners for terrestrial digital

broadcasting high definition radios, both for the U.S. market. Sales of multimedia

and mechanical systems fared well, and the Company stepped up their

production. Accordingly, its OEM business expanded remarkably.

In the communications business, the Company focused on developing digital

radio communication terminals and radio communication systems in response to

the digitalization wave affecting radio communication domain.

In the home electronics business, the Company, concentrating its efforts on

home theater systems, pure audio equipment and portable audio devices,

developed digital amplifiers with high quality and next-generation network-based

audio systems, as well as products with excellent tone quality by stepping up

research on tone quality.

Reinforcement of the brand

After its start as a reborn Kenwood, the Company strove to rebuild its brand,

aiming to increase its global presence. In January 2004, the Company launched a

brand management project, in which Group staff around the world joined, to

work on a brand strategy to provide new value to the market. The Company also

signed an official supplier contract with McLaren-Mercedes Racing to provide the

renowned team with its radio communication equipment for the Formula One (F-

1) world auto-racing championship.

Kenwood Corporation 13